The engine removal guide will tell you how to get your 7M out the car and then this guide will tell you what to do with the engine when it's out. The only missing section is where I had to strip off all the ancillaries quite quickly to get the engine in my boot. Basically all the manifolds, brackets etc were very quickly stripped off leaving a bare engine ready for stripdown.

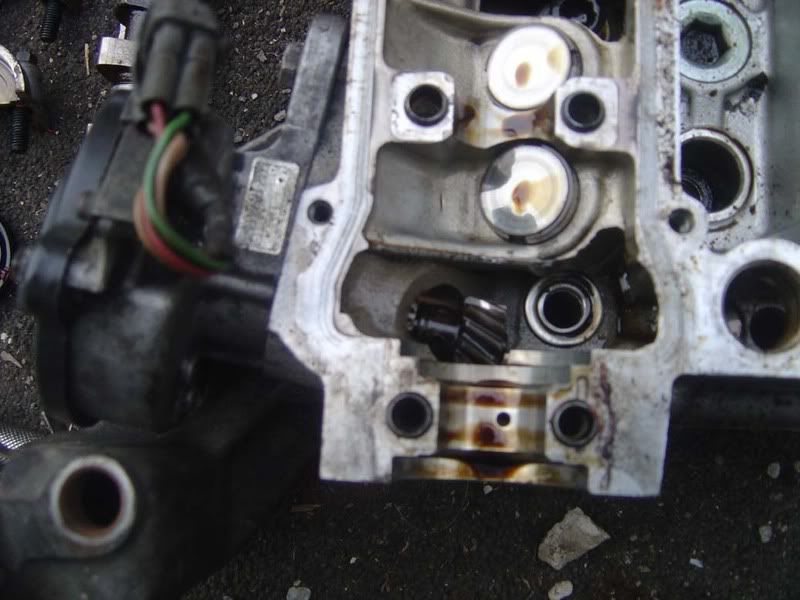

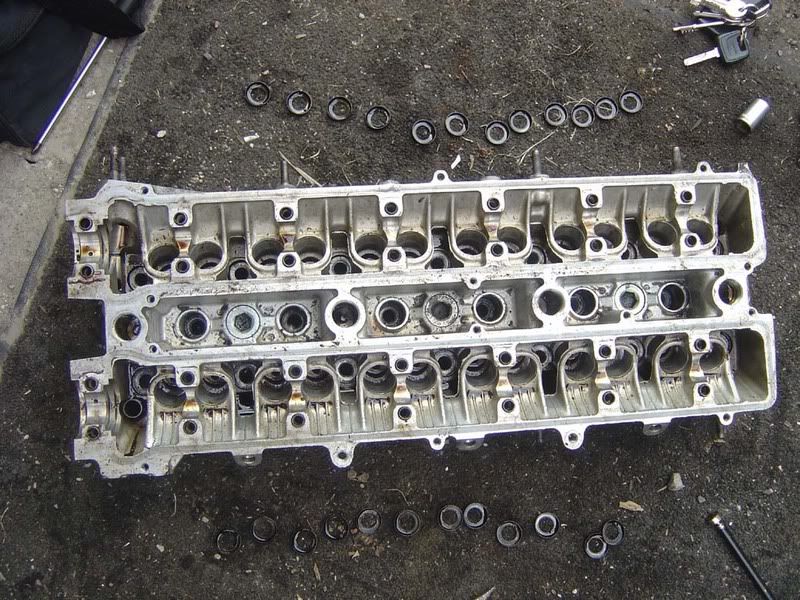

Step 1 - We'll start by removing the cam covers. There's a guide that covers removal of everything to get to the cam covers which might come in handy. If your car is anything like mine then you'll have the stock Toyota screws, random 10mm bolts and allen keys thrown in here!

Note you will have to remove the bracket to support the 3000 pipe (as shown in picture 4) to get the final bolt out on the exhaust side)

Step 2 - Tilt the cam covers to the side to free from the gasket

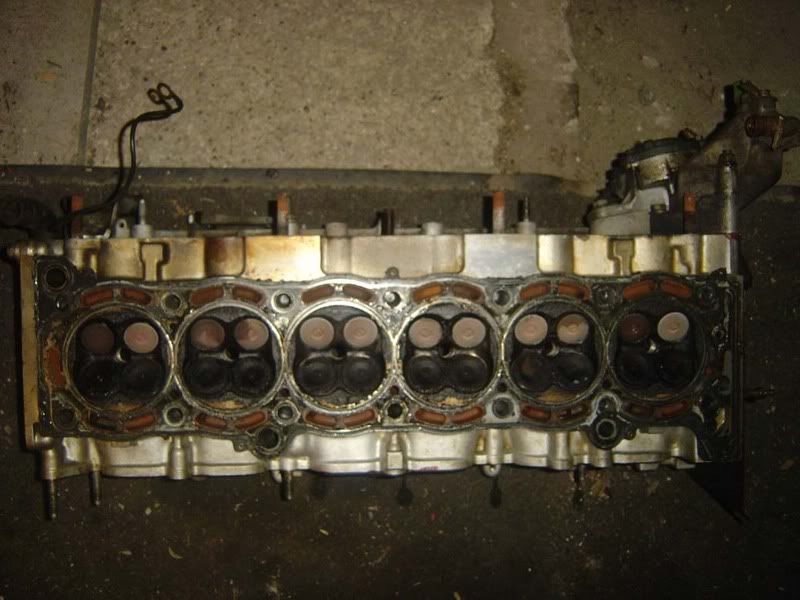

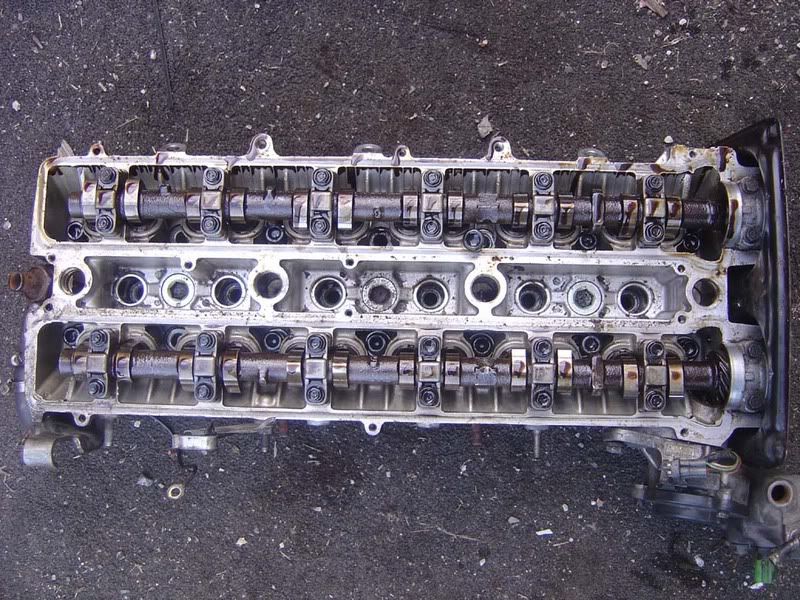

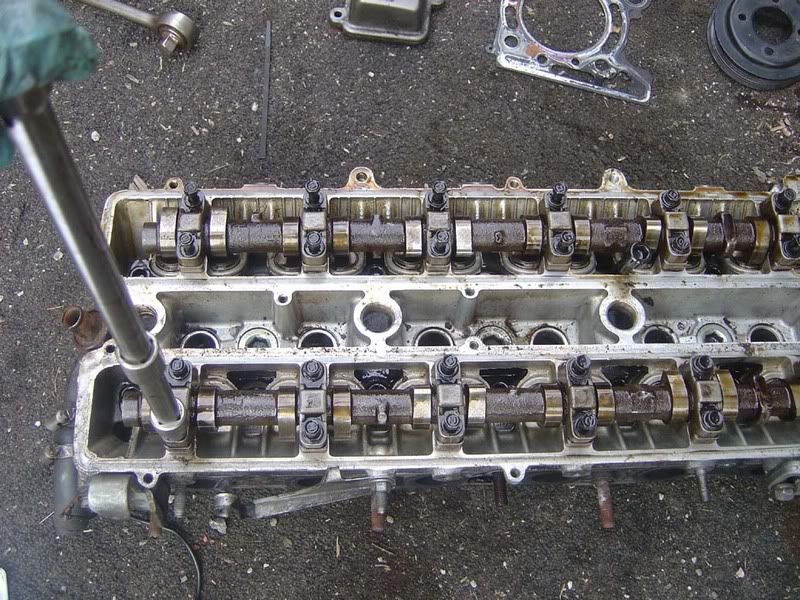

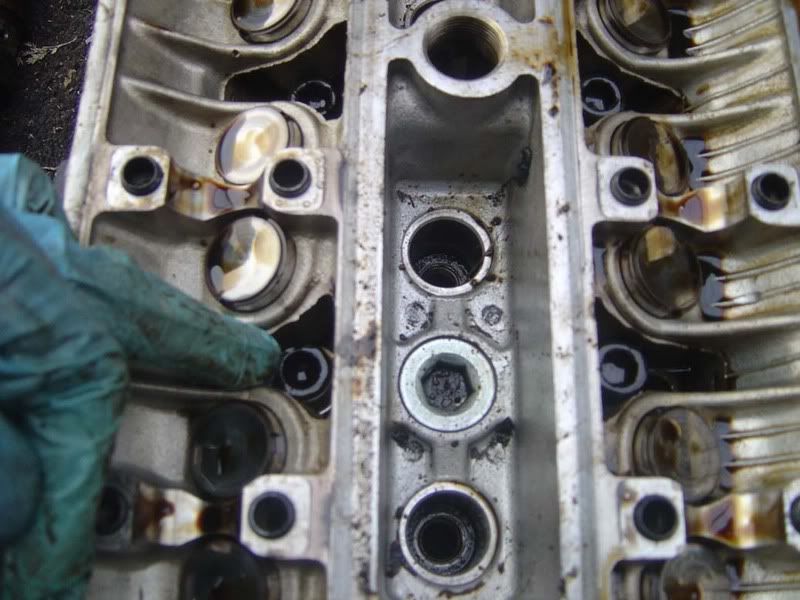

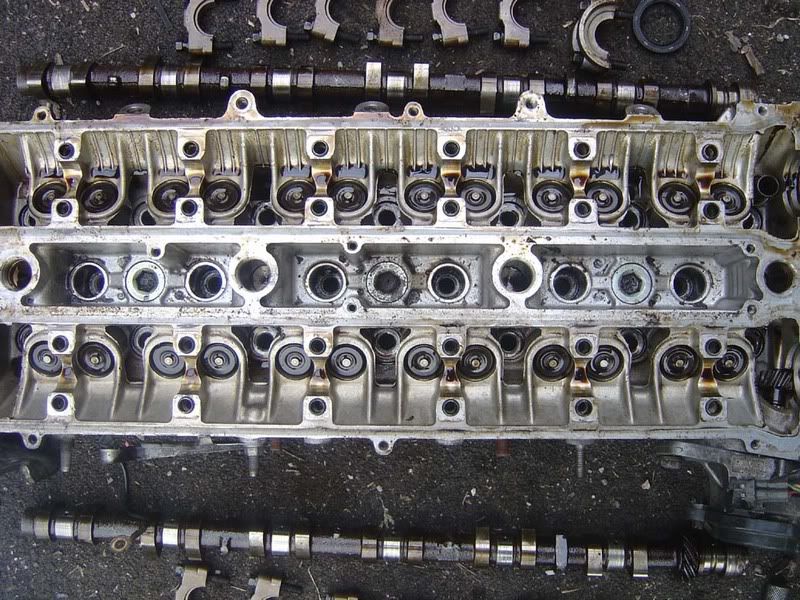

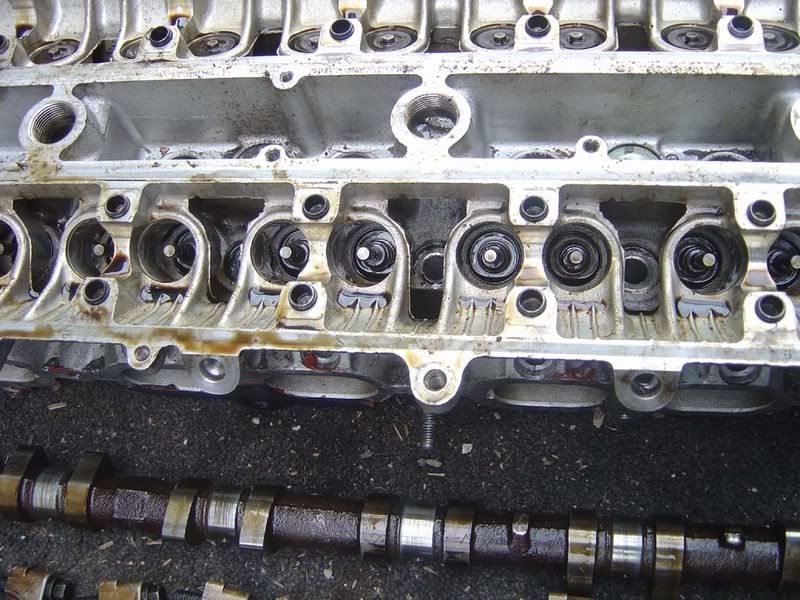

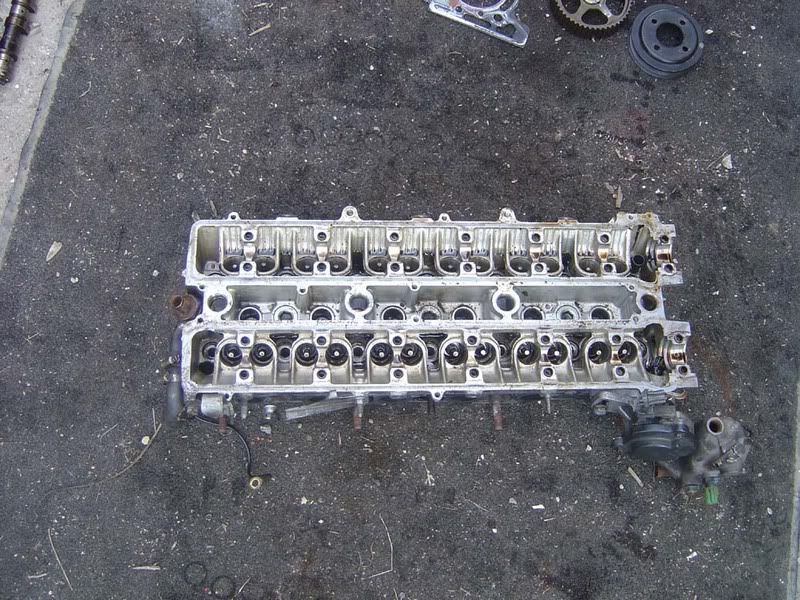

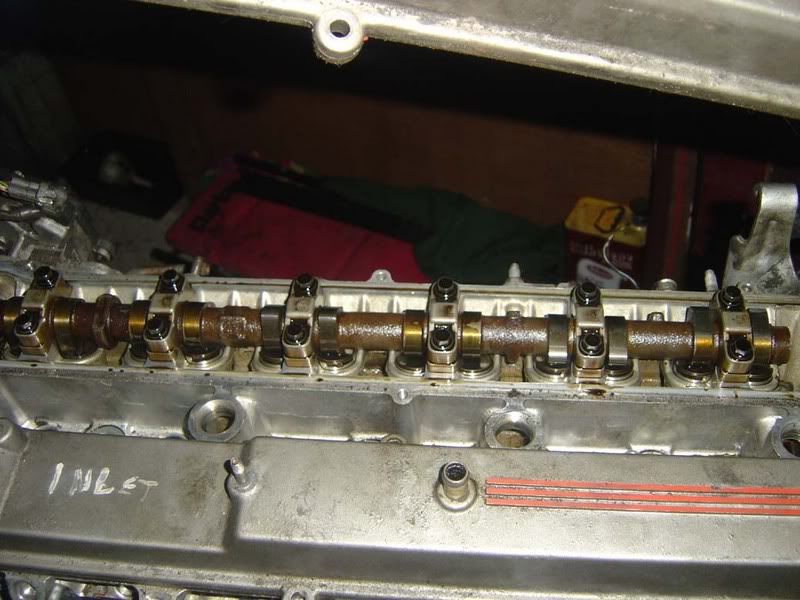

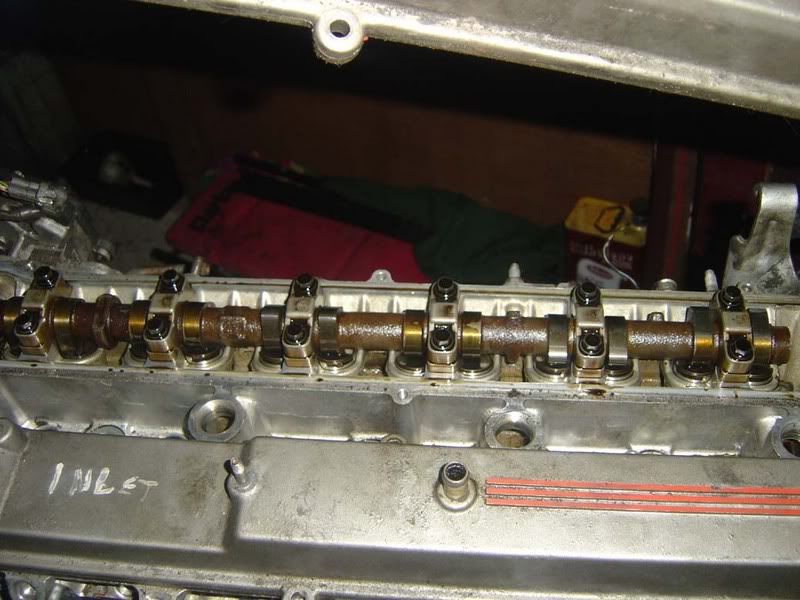

Step 3 - Now remove each cover to reveal the camshafts

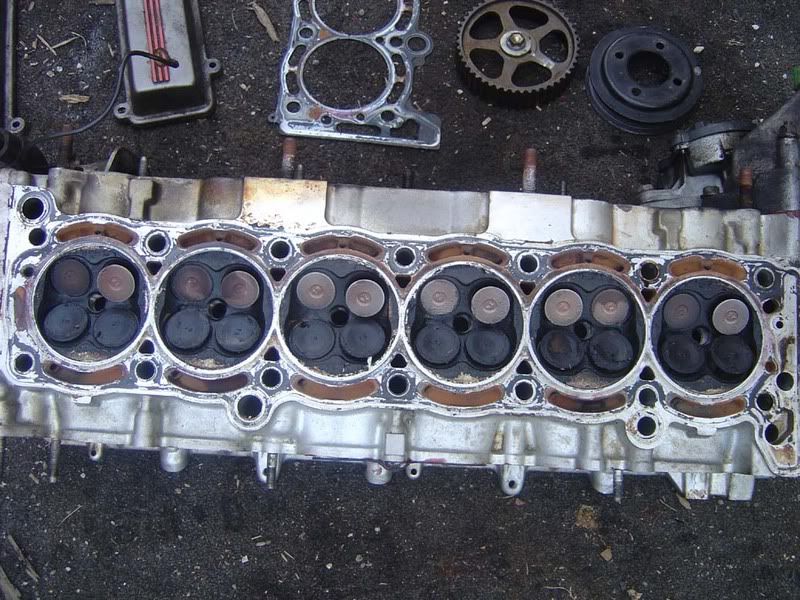

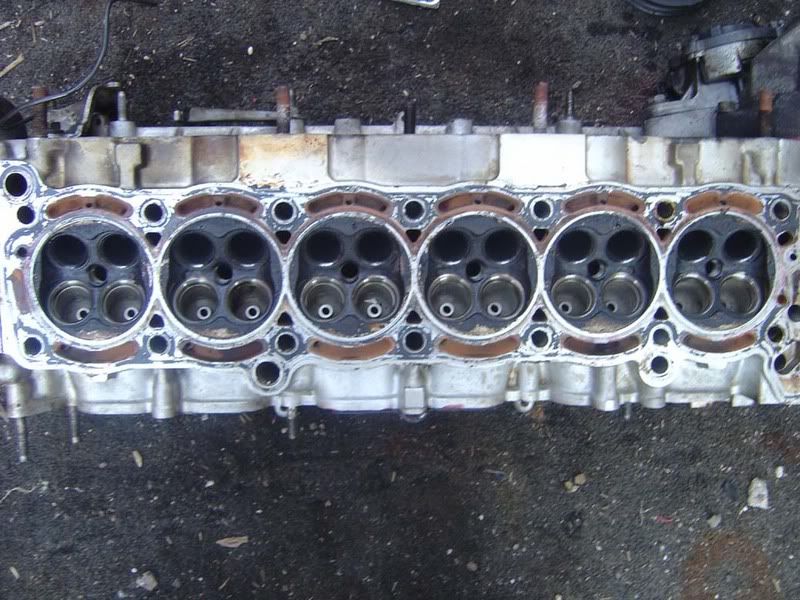

Step 4 - As with anything you remove, clean it up thoroughly then fit a new gasket when you put it back on. A toyota head gasket set will have most of what you need in it for about £80

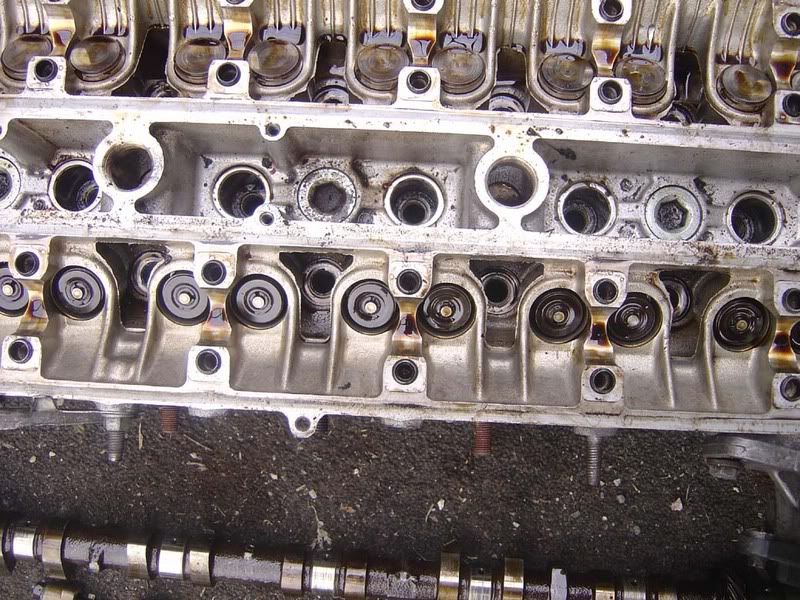

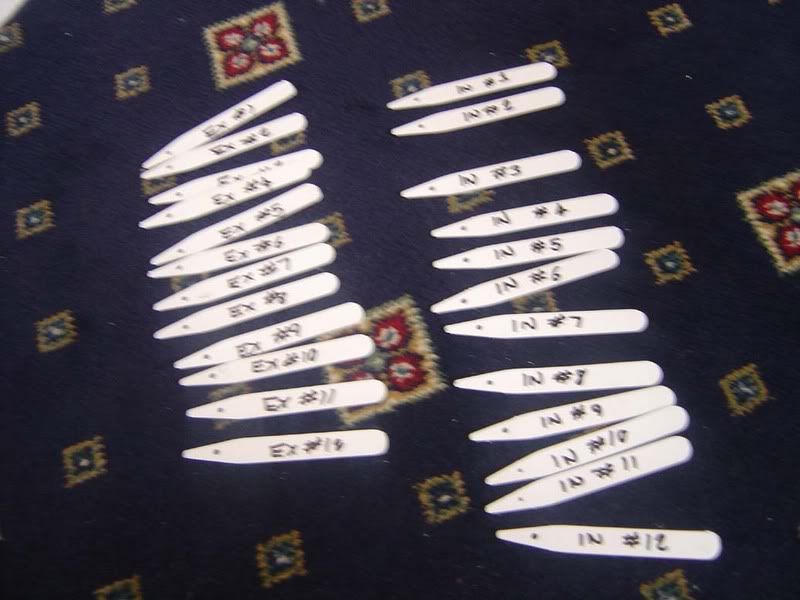

Step 5 - Cylinder head bolts are next. The head bolts are torqued quite high (not high enough from Toyota but that's a different story!), so will need a fair amount of force to shift. You should invest in either a long 10mm allen key socket or just hacksaw the small end off an allen key and fit that to a standard 10mm socket. Use a breaker bar to get the leverage you need and try to use a fluid motion rather than shocking the bolts by hitting the bar with a hammer. I always remove the head bolts in several stages:

1. 'Crack off' the bolts by which I mean move them about 1/8th - 1/4 of a turn

2. Turn each bolt a further 1/2 - 1 turn

3. Remove the bolts

This is always done in the sequence shown below -

INLET

BACK 4 8 12 14 9 5 1 FRONT

BACK 2 6 10 13 11 7 3 FRONT

EXHAUST

It's very important you use the correct sequence to minimise stress to the cylinder head. The head should be treated carefully as it is soft (aluminium) and can easily be stressed/damaged.

The third picture shows a 10mm torx style extension bar which will do the trick if you can't get an allen key one

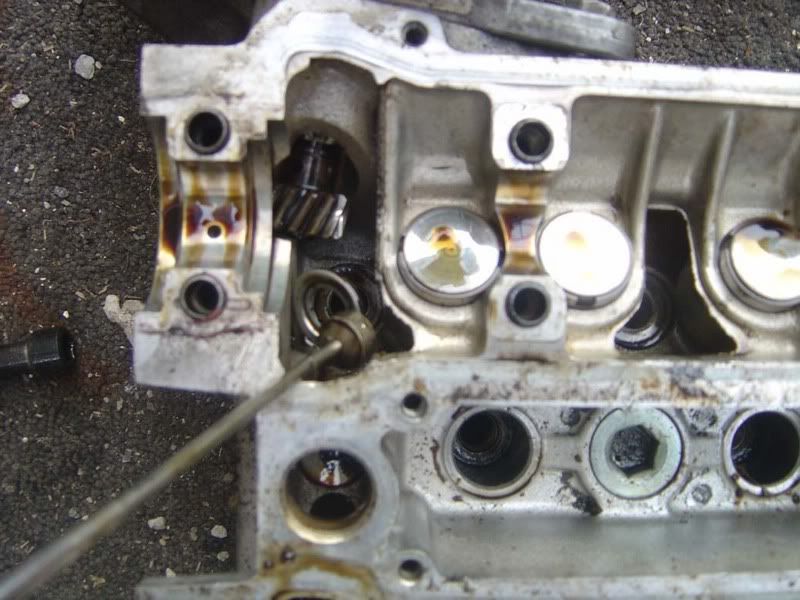

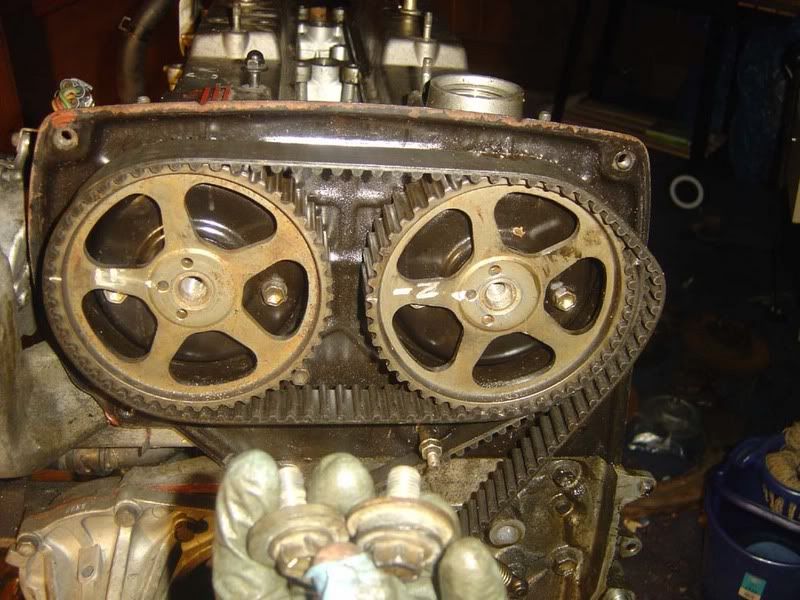

Step 6 - Follow the cam belt removal guide until step 17 i.e. all the stripdown stuff but none of the rebuild

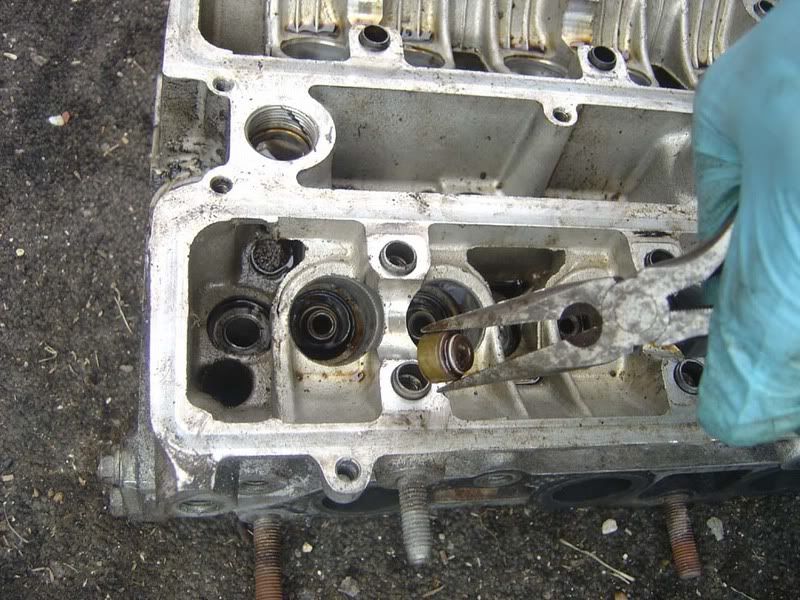

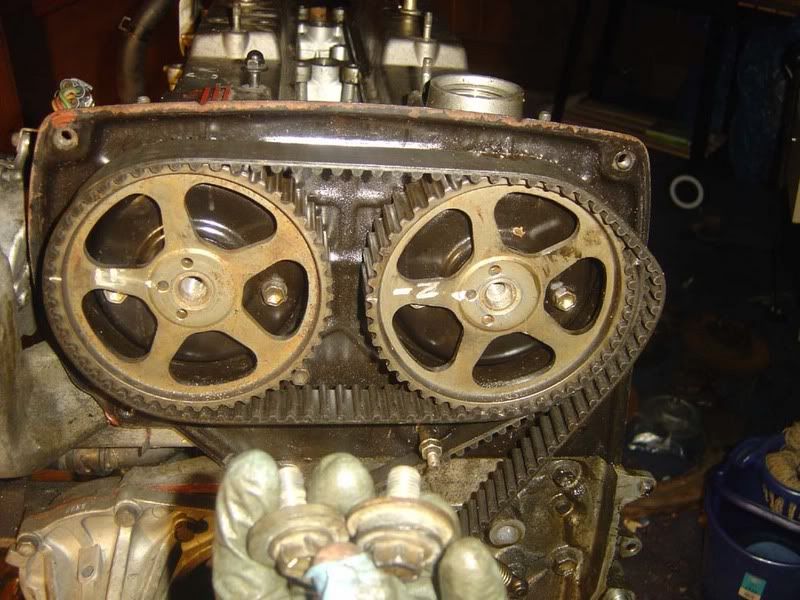

Step 7 - You need to lock the cam pulleys now which can be done with special service tools from Toyota (SSTs) or by fabricating your own. I just re-used the old cam belt I was going to throw away by wrapping it over both cam pulleys and the belt's idler pulley. This locked the wheels so I could crack off the 14mm centre nut

Step 8 - The nuts should be easy to undo once they've been cracked off so you can now remove them by hand.

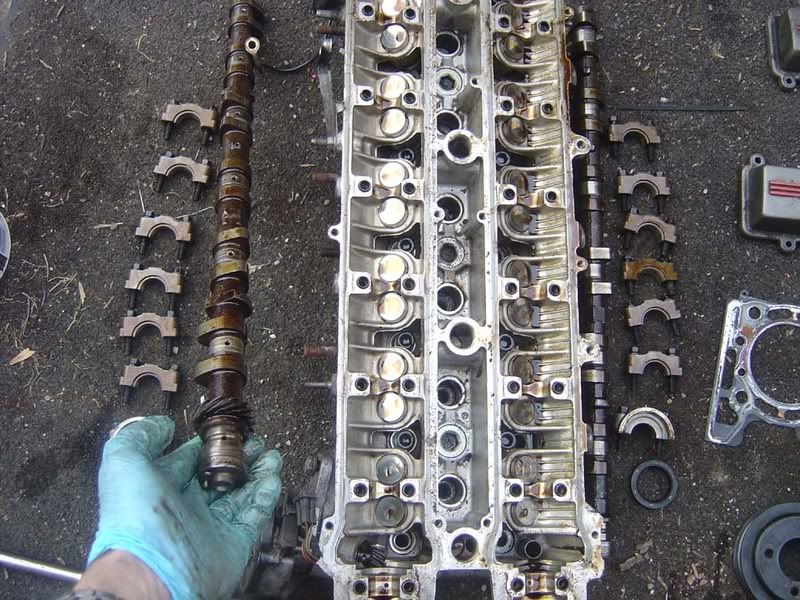

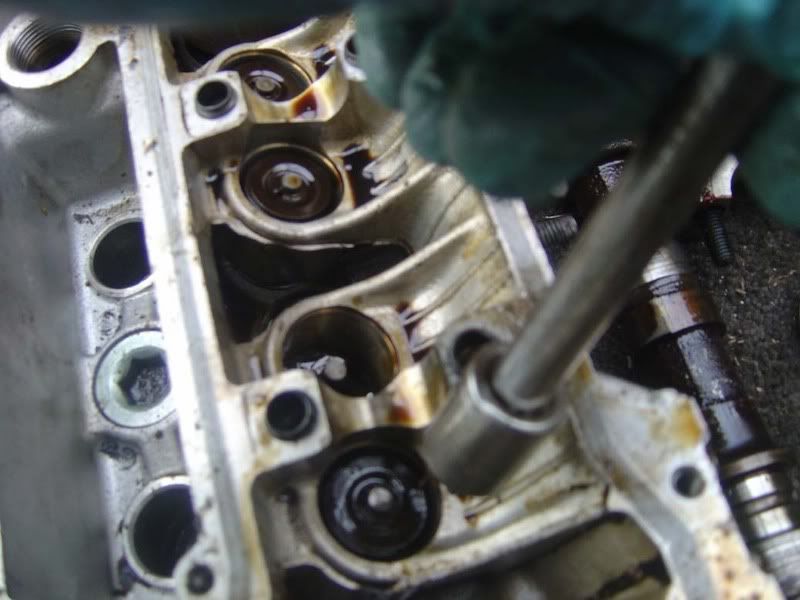

Step 9 - When you have removed the pulleys you will see there is a dowel in the camshaft that aligns with the centre of 3 holes in the pulley itself, you'll need this on refitting. Both pulleys are identical

Step 1 - We'll start by removing the cam covers. There's a guide that covers removal of everything to get to the cam covers which might come in handy. If your car is anything like mine then you'll have the stock Toyota screws, random 10mm bolts and allen keys thrown in here!

Note you will have to remove the bracket to support the 3000 pipe (as shown in picture 4) to get the final bolt out on the exhaust side)

Step 2 - Tilt the cam covers to the side to free from the gasket

Step 3 - Now remove each cover to reveal the camshafts

Step 4 - As with anything you remove, clean it up thoroughly then fit a new gasket when you put it back on. A toyota head gasket set will have most of what you need in it for about £80

Step 5 - Cylinder head bolts are next. The head bolts are torqued quite high (not high enough from Toyota but that's a different story!), so will need a fair amount of force to shift. You should invest in either a long 10mm allen key socket or just hacksaw the small end off an allen key and fit that to a standard 10mm socket. Use a breaker bar to get the leverage you need and try to use a fluid motion rather than shocking the bolts by hitting the bar with a hammer. I always remove the head bolts in several stages:

1. 'Crack off' the bolts by which I mean move them about 1/8th - 1/4 of a turn

2. Turn each bolt a further 1/2 - 1 turn

3. Remove the bolts

This is always done in the sequence shown below -

INLET

BACK 4 8 12 14 9 5 1 FRONT

BACK 2 6 10 13 11 7 3 FRONT

EXHAUST

It's very important you use the correct sequence to minimise stress to the cylinder head. The head should be treated carefully as it is soft (aluminium) and can easily be stressed/damaged.

The third picture shows a 10mm torx style extension bar which will do the trick if you can't get an allen key one

Step 6 - Follow the cam belt removal guide until step 17 i.e. all the stripdown stuff but none of the rebuild

Step 7 - You need to lock the cam pulleys now which can be done with special service tools from Toyota (SSTs) or by fabricating your own. I just re-used the old cam belt I was going to throw away by wrapping it over both cam pulleys and the belt's idler pulley. This locked the wheels so I could crack off the 14mm centre nut

Step 8 - The nuts should be easy to undo once they've been cracked off so you can now remove them by hand.

Step 9 - When you have removed the pulleys you will see there is a dowel in the camshaft that aligns with the centre of 3 holes in the pulley itself, you'll need this on refitting. Both pulleys are identical