The throttle position sensor can make a massive difference to the way your car performs. If it is out of calibration you may find you can't set the timing up prpoerly and it will change throttle response significantly. It's a bit of a pain to set up but well worth it in my opiniong (Having driven a car with a poorly adjusted TPS and reaped the rewards of fixing it!)

Step 1 - fOllow the guide for removing the PCV system (Note in the pictures the cam covers have been removed but you don't need to. Also follow steps 2 and 3 in the cam cover guide

Step 2 - Look inside the throttle body to see if there is a black buil up of carbon deposits (If so, you should use carb cleaner to flush it out - I'd remove the throttle body to do it properly but it's up to you)

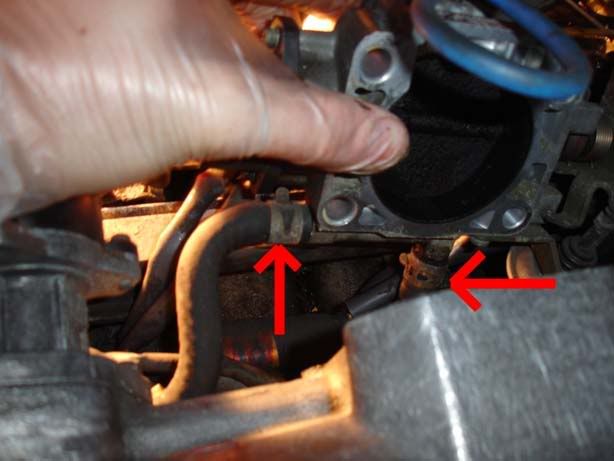

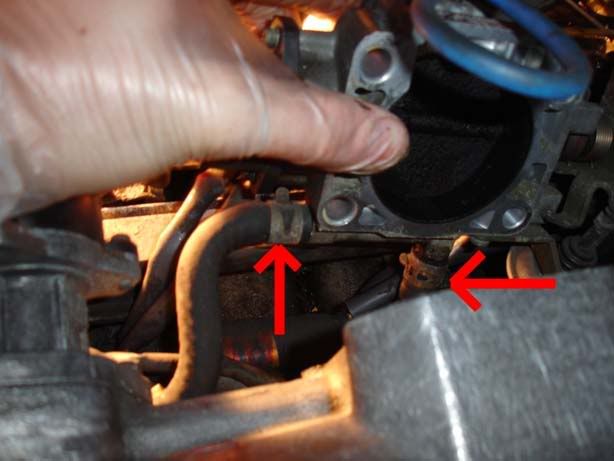

Step 3 - You should check thet the throttle stop (The little screw bit) is in contact with the throttle lever (The springy bit that gets pulled when you press the accelerator) when the accelerator is released. Note that I am moving the two apart so you can see which two bits I mean

Step 4 - Disconnect the connector to the Throttle Position Sensor

Step 5 - The 4 connections you see here for the TPS are E2, IDL, VTA and VC. You use the electrical resistance between these 4 pins to set up the sensor

Step 6 - Insert a feeler gauge between the throttle stop and lever (as in step 3) and measure the resistance* as shown below :

NOTE : These are for a 7MGTE, see the TSRM for a 7MGE

With no feeler gauge fitted you should find between 0.2 and 1.2 Kilo ohms of resistance between VTA and E2

With a feeler gauge of 0.5mm inserted between the stop and lever you should measure a resistance of 2.3 kilo ohms between IDL and E2

With a feeler gauge of 0.9mm inserted between the stop and lever you should measure an inifinite resistance (Shown as a 1 for no continuity on your meter) between IDL and E2

Finally, with the throttle fully open you should have 3.5-10.3 kilo ohms between VTA and E2 as well as 4.25 - 8.25 kilo ohms between VC and E2

If you don't comply to these then you need to calibrate your TPS

*To measure the resistance you will need a bog standard multimeter. Switch it to "ohms" to measure resistance - this is the one that is like a circle but has two flats at the bottom

Step 7 - If you need to calibrate the throttle body then it needs to be removed from the car (you can't get to the bottom screw of the TPS without removing other components). Start by undoing the 4 bolts holding the throttle body to the inlet plenum

Step 8 - If you ease the throttle body away from the plenum you will find there are two water bypass hoses attached to it

Step 9 - Remove the hoses shown on the left in picture 8 from the other end (by the VSV) as shown in the first picture. The second hose is removed directly from the throttle body (a bit fiddly but use a monkey wrench to expand the clip then work it down the pipe) as shown in the second picture

Step 10 - Remove the throttle body and take it somewhere warm to work (assuming it's thrashing it down with rain like when I did mine!)

Step 1 - fOllow the guide for removing the PCV system (Note in the pictures the cam covers have been removed but you don't need to. Also follow steps 2 and 3 in the cam cover guide

Step 2 - Look inside the throttle body to see if there is a black buil up of carbon deposits (If so, you should use carb cleaner to flush it out - I'd remove the throttle body to do it properly but it's up to you)

Step 3 - You should check thet the throttle stop (The little screw bit) is in contact with the throttle lever (The springy bit that gets pulled when you press the accelerator) when the accelerator is released. Note that I am moving the two apart so you can see which two bits I mean

Step 4 - Disconnect the connector to the Throttle Position Sensor

Step 5 - The 4 connections you see here for the TPS are E2, IDL, VTA and VC. You use the electrical resistance between these 4 pins to set up the sensor

Step 6 - Insert a feeler gauge between the throttle stop and lever (as in step 3) and measure the resistance* as shown below :

NOTE : These are for a 7MGTE, see the TSRM for a 7MGE

With no feeler gauge fitted you should find between 0.2 and 1.2 Kilo ohms of resistance between VTA and E2

With a feeler gauge of 0.5mm inserted between the stop and lever you should measure a resistance of 2.3 kilo ohms between IDL and E2

With a feeler gauge of 0.9mm inserted between the stop and lever you should measure an inifinite resistance (Shown as a 1 for no continuity on your meter) between IDL and E2

Finally, with the throttle fully open you should have 3.5-10.3 kilo ohms between VTA and E2 as well as 4.25 - 8.25 kilo ohms between VC and E2

If you don't comply to these then you need to calibrate your TPS

*To measure the resistance you will need a bog standard multimeter. Switch it to "ohms" to measure resistance - this is the one that is like a circle but has two flats at the bottom

Step 7 - If you need to calibrate the throttle body then it needs to be removed from the car (you can't get to the bottom screw of the TPS without removing other components). Start by undoing the 4 bolts holding the throttle body to the inlet plenum

Step 8 - If you ease the throttle body away from the plenum you will find there are two water bypass hoses attached to it

Step 9 - Remove the hoses shown on the left in picture 8 from the other end (by the VSV) as shown in the first picture. The second hose is removed directly from the throttle body (a bit fiddly but use a monkey wrench to expand the clip then work it down the pipe) as shown in the second picture

Step 10 - Remove the throttle body and take it somewhere warm to work (assuming it's thrashing it down with rain like when I did mine!)