Dyno tuning video with the GT42

- Thread starter X-man

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zazzn said:awesome xman! I bearly pulled my friends 18 PSI gt42 7m powered supra in my 1jz @ 20 psi with the k26 twins.

That thing is gonna be a beast... btw, looks like you are going to have to turn up that rev limit... Under 2k of power is a lil annoying!! I'm sure with a little anti lag settings on the AEM and some fooling aroudn you can pull 200-300 RPM back of spool.

can't wait for the final result.

I'm hoping that when I turn the boost controller on that this will help alittle with spool up also. I have the rev limit set at 7500 rpm but after 6500 rpm the car was still going rich so it was breaking up. The last pull before the manifold cracked it did make 7000 rpm but I was more worried about a/f's.

Supra87t/t4 any of the manifolds I have seen built have at least one or two long welds on a sharp edge. The backfire in the manifold was violent and split the manifold open by at least an inch. I'm not saying that I'm the best welder or that this is the best design, but it has built alot of horsepower over the stock manifold for me and has taken alot of abuse at 20 psi and above. I might just have to come up with better bracing for it or build it out of 6061 aluminum instead of 4043. It doesn't cost me anything but an intake gasket and time to fix so I'll get it worked out.:icon_bigg

Sean

Good numbers considering the AFR, I'm dipping into the 9s at WOT:nono:

Sucks about the mani, I think I'd cry if I split mine open.

Sucks about the mani, I think I'd cry if I split mine open.

Obviously the big backfire is well beyond the normal stress on the manifold, but speaking from my own experience a design that has those corners bent into the sheet is much stronger than welding two flat sheets at 90*. I mentioned it in one of your other threads and I'm not too suprised to hear it ended up cracking. I had the same problem with some intercooler endtanks I made that way, the next set I bent those two long corners and didn't have any more problems. It's a bit more work, but see if you can find someone to bend that up for your next one, plus it's that much less that you have to weld.

Glen

Glen

supra87t/t4 said:Obviously the big backfire is well beyond the normal stress on the manifold, but speaking from my own experience a design that has those corners bent into the sheet is much stronger than welding two flat sheets at 90*. I mentioned it in one of your other threads and I'm not too suprised to hear it ended up cracking. I had the same problem with some intercooler endtanks I made that way, the next set I bent those two long corners and didn't have any more problems. It's a bit more work, but see if you can find someone to bend that up for your next one, plus it's that much less that you have to weld.

Glen

I agree about the bending instead of welding, but I didn't have anyone around who could bend three sides that tight. They could have bent up two sides but I still would have had too weld the back and front in. I have been thinking about bending some up some 1 inch angle and capping the welds, but I'm not sure how that will look. I know a guy that builds manifolds that has come up with some type of bracing system on ones he sells, but I will have too see what that is.

Sean

dbsupra90 said:i was just trying to make a point that it did fine prior to the stick of tnt inside it. it held up fine multiple beatings of 25-30psi w/ the sp67 on it.

Agreed and the issue this time I believe was a hasty repair made by the dumbass building the car.:biglaugh:

Sean

supra87t/t4 said:Obviously the big backfire is well beyond the normal stress on the manifold, but speaking from my own experience a design that has those corners bent into the sheet is much stronger than welding two flat sheets at 90*. I mentioned it in one of your other threads and I'm not too suprised to hear it ended up cracking. I had the same problem with some intercooler endtanks I made that way, the next set I bent those two long corners and didn't have any more problems. It's a bit more work, but see if you can find someone to bend that up for your next one, plus it's that much less that you have to weld.

Glen

I disagree, a proper penetration welded joint will be far stronger than a folded edge, especially in such thin gauge metal. Unless of course you try to make it look pretty afterwards and grind the welds down, then it will crack, especially in an area that can only be welded from the outside.

Mine didn't blow up though, just a crack.

Re-welded

[/hijack]

Last edited:

blackout_89t said:I disagree, a proper penetration welded joint will be far stronger than a folded edge, especially in such thin gauge metal. Unless of course you try to make it look pretty afterwards and grind the welds down, then it will crack, especially in an area that can only be welded from the outside.

[/hijack]

How do you think a formed (bent) corner is going to fail? There is no welding to weaken the base metal and nowhere for a crack to start, the bend will leave some radius in the corner and that reduces the stress compared to a "sharp" corner made by two plates. The way alot of these manifolds are made you end up welding the thinner sheet to a thicker plate at the joint you are showing, in that case you don't have alot of choice, I was referring more to the other joint where the two thin plates join, which I can't really see in your pics.

Give me some credit, I basically predicted the failure and suggested a possible improvement from my own experience. Sean's cracking may have never hapened without the backfire and it may be fixed with different material or welding. A properly welded corner in the right material and thickness will no doubt do the job, but there's no way it's stronger than a formed corner in the same material.

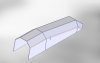

In my opinion, yes, of course you will still have to weld that onto a base of some kind. I'm not trying to say it can't be made strong enough with welded corners, of course it can, but I have no doubt that it will be stronger the way you have modeled it, does that make it "better", that's personal preference I guess.

Looks like it was modeled in SolidWorks, did you use the sheetmetal tools so that you can make the flat pattern?

Looks like it was modeled in SolidWorks, did you use the sheetmetal tools so that you can make the flat pattern?

A proper welded joint is stronger than the base metal, it will also be thicker, and to an extent make the surrounding base material stronger through heat treating, although more brittle.

The radius in the corner for stress relief doesn't really matter as the stress in the material itself at rest is irrelevant. Although, the bent corner will actually have more stress at rest than the welded joint will as the permanent deformation to the material in the bend brings it passed its yield strength. This makes it prone to failure having any more force applied to this area.

Poisson's ratio also comes into effect with the bent corner which is another argument in itself...

To each their own, either design will suffice for this application.

The radius in the corner for stress relief doesn't really matter as the stress in the material itself at rest is irrelevant. Although, the bent corner will actually have more stress at rest than the welded joint will as the permanent deformation to the material in the bend brings it passed its yield strength. This makes it prone to failure having any more force applied to this area.

Poisson's ratio also comes into effect with the bent corner which is another argument in itself...

To each their own, either design will suffice for this application.

supra87t/t4 said:How do you think a formed (bent) corner is going to fail? There is no welding to weaken the base metal and nowhere for a crack to start, the bend will leave some radius in the corner and that reduces the stress compared to a "sharp" corner made by two plates. The way alot of these manifolds are made you end up welding the thinner sheet to a thicker plate at the joint you are showing, in that case you don't have alot of choice, I was referring more to the other joint where the two thin plates join, which I can't really see in your pics.

Give me some credit, I basically predicted the failure and suggested a possible improvement from my own experience. Sean's cracking may have never hapened without the backfire and it may be fixed with different material or welding. A properly welded corner in the right material and thickness will no doubt do the job, but there's no way it's stronger than a formed corner in the same material.

Last edited: