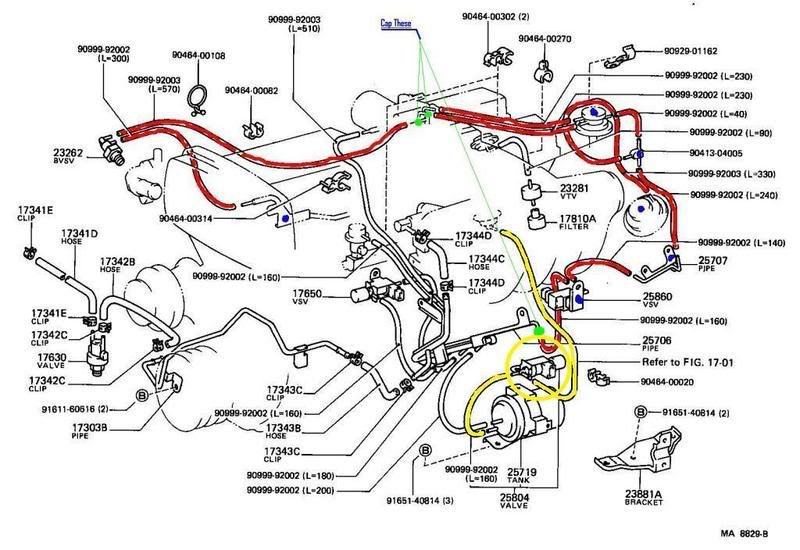

Acoustic Controlled Induction System.

It consists of a simple butterfly valve (just like your throttle body) underneath that twin can 24 valve sticker you have. You can unscrew that rectangular plate and view into the intake and this valve.

Its purpose, as I understand it is to allow for the adjustment between short and long "runners", or channels of intake air flow.

When you're at lower rpms, the air can be mixed in the plenum with negligible effects. Once you hit about 4200 rpms, the ACIS kicks in and closes the butterfly valve which now creates two long channels of air, each of which feeds 3 pipes for the intake(sorry dont know the name of each pipe :dunce: ).

***Now here's where I'm hypothesizing***

The way i figure, when one of your cylinder's intake valves close, it causes a rush of air. The air has nowhere to go for a split second. This creates an area of high pressure. When the air is divided and kept in two sections with the ACIS, this pressure increase is notable every time a valve closes. I'm picturing that if the valve weren't there the air would not pressurize as much because it has so much more space to work with. When the next valve opens, the pressurized air is sucked/pushed into the cylinder. This results in slightly more air being pulled into the cylinder.

And woolah! You get a *tiny* little extra power..... supposedly.

***end of my idea*** (experts please weigh in if I was off anywhere

)

Every now and then i can notice my engine pep up just a slight bit @ ~4200 rpm, but it doesn't seem to make any sort of difference on the highway in 3rd gear past 4000rpm. Really just 1st and 2nd gear.

Hope that helps and I hope *most* of my hypothesis was right. My fluid dynamics teacher is horrible though, so if its wrong, i blame it on her