Just install it so the convex side is out, and tap it in the center with a hammer to 'pin' it in place, right?

Never installed a disc plug, so I thought I'd check

Never installed a disc plug, so I thought I'd check

87witmoreboost;1409331 said:To add to the last question, what is the conclusive way to install this disc plug? How the hell can it hold much of any pressure with so little outer surface area on the bore in the block?

And a simple freeze plug question - does the lip of the plug have to be flush with the block? What if it is recessed a bit? If hammered in too hard, would it go through to the water jacket?

I tried installing my plugs tonight and felt like I had an epic fail when the plugs on the exhaust side all recessed beyond the block surface and now I am afraid I need a new set of plugs. I was fighting the "do it in the smallest amount of hits possible" vs. "dont hit TOO hard".

Help?

87witmoreboost;1409331 said:To add to the last question, what is the conclusive way to install this disc plug? How the hell can it hold much of any pressure with so little outer surface area on the bore in the block?

87witmoreboost;1409331 said:To add to the last question, what is the conclusive way to install this disc plug? How the hell can it hold much of any pressure with so little outer surface area on the bore in the block?

And a simple freeze plug question - does the lip of the plug have to be flush with the block? What if it is recessed a bit? If hammered in too hard, would it go through to the water jacket?

I tried installing my plugs tonight and felt like I had an epic fail when the plugs on the exhaust side all recessed beyond the block surface and now I am afraid I need a new set of plugs. I was fighting the "do it in the smallest amount of hits possible" vs. "dont hit TOO hard".

Help?

lewis15498;1409342 said:There really isnt a lot of pressure in the cooling system, not enough to pop a freeze plug anyway.

I reccomend using a socket of slightly smaller size to apply even pressure and tap it in very lightly.

jdub;1409371 said:A freeze plug is a press fit...the diameter of the plug is slightly larger than the hole in the block. The machined sealing surface in the block is recessed a bit...some more than others. If you look at the installed plug, the lip should be even with the machined surface...if the plug is intoo far, you'll see that surface. If it is not in far enough, you will feel a small screw driver catch on the lip if you pick at it.

You don't have to worry about the plug interfering with the coolant passage. You do have to worry about driving it into the block though

Yeah there is, I've popped two...it's not pretty. On the 1st motor, I used Dorman plugs. Turns out they are on the English measuring system...Toyota plugs are metric and are about 5-6 thou larger in diameter. The Toyota plugs are steel and fit a lot tighter over time in a steel block.

You want to install a plug with one good whack otherwise you can pull in the sides due to the shape of the plug and where the force is applied (at the inside dome). Tapping is almost a sure fire way to make sure it won't seal on a 7M. Not a chance in hell I'd recommend tapping it in.

Or, you can use a tool like this:

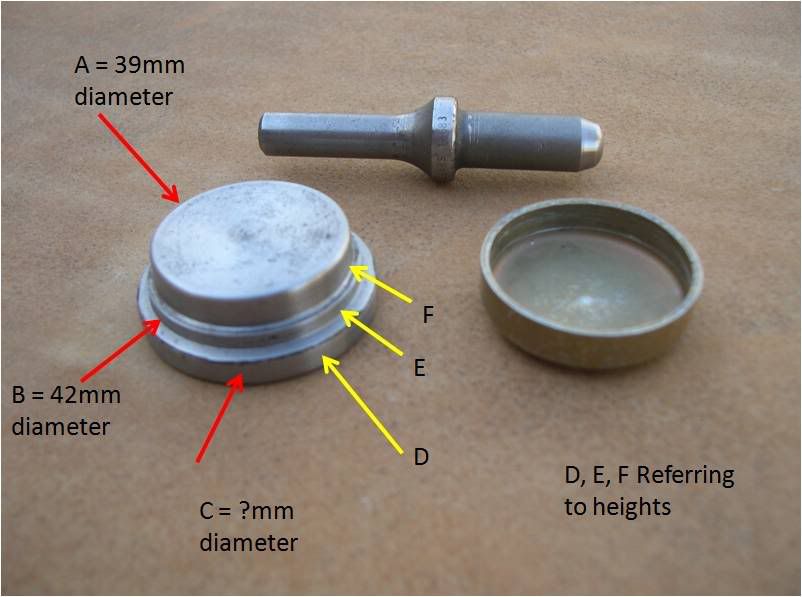

You use an air hammer and disk to drive the plug in. Force is applied to the edge of the plug, so you don't have the problem above. I also made this custom disk for the sides of the block:

The front passenger side plug is recessed more than the others...this disk allows me to drive the plug all the way in past the recess.

You can see what I'm talking about putting force on the edge on these pics as well.

jdub;1409555 said:The cap does regulate pressure....it's spec'ed at 10.7-14.9 psi. It's plenty to force out an improperly installed plug.

lewis15498;1409558 said:So only if its installed incorrectly? If you do it right can this still happen?

jdub;1409569 said:and then there's the genius that thinks running a jdm tyte high pressure cap is a good idea :nono:

jdub;1409623 said:A = 36.8mm

B = 40.3mm

C = 45.7mm

D = 6.5mm

E = 3.4mm

F = 6.6mm