Just scratching the surface man.

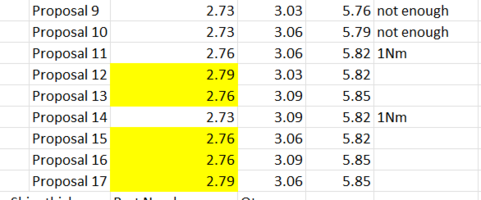

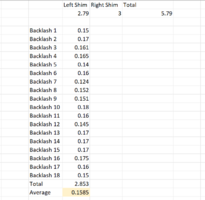

The fun is when 1 change or adjustment affects 3 others.

Have to really understand the relationship between everything to hit your targets correctly.

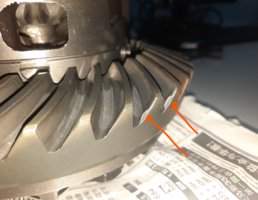

Landing a perfect gear mesh is my peak elation on a diff build.

Once that lands into place the rest becomes lock step.

The fun is when 1 change or adjustment affects 3 others.

Have to really understand the relationship between everything to hit your targets correctly.

Landing a perfect gear mesh is my peak elation on a diff build.

Once that lands into place the rest becomes lock step.