Diesel Engines and Compression in relation to a Petrol Engine (say.. 7MGTE)

- Thread starter vas85

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

man you guys all are over the place

the reason most disels dont rev high is because they have a long stroke they have the same mean piston speed or even higher then automotive applications

the reason disels are noiseing is the rapid increase in clyinder pressure at ignition

FORD IS NOT THE ONLY COMPANY USING PILOT INJECTION such a statment makes me red in the face espeically since ford doesnt make their disel motors international does so please dont talk unless you know what your talking about

if you take the stroke away from a disel then it cant rev higher its all a balancing act

noise is reduced on disels by pilot injection and gear train noise reduction ie tuned time covers sprung front gears helical cut gears and all sorts of other little tricks

so in summary what limits a disels speed is the mean piston speed which relates to your stoke

THE FUEL SYSTEM IS NOT THE LIMIT if i told you what our fuel system is capable of you wouldnt belive me

the noise is due to rapid cylinder pressure increase on ignition

the reason most disels dont rev high is because they have a long stroke they have the same mean piston speed or even higher then automotive applications

the reason disels are noiseing is the rapid increase in clyinder pressure at ignition

FORD IS NOT THE ONLY COMPANY USING PILOT INJECTION such a statment makes me red in the face espeically since ford doesnt make their disel motors international does so please dont talk unless you know what your talking about

if you take the stroke away from a disel then it cant rev higher its all a balancing act

noise is reduced on disels by pilot injection and gear train noise reduction ie tuned time covers sprung front gears helical cut gears and all sorts of other little tricks

so in summary what limits a disels speed is the mean piston speed which relates to your stoke

THE FUEL SYSTEM IS NOT THE LIMIT if i told you what our fuel system is capable of you wouldnt belive me

the noise is due to rapid cylinder pressure increase on ignition

IJ. said:Rudolf Christian Karl Diesel invented them note how he spells it......

come on IJ just because i dont ever use spell check or grammer or read what i just typed doesnt mean you have to make fun of me :cry:

But it helps when trying to display an idea or facts you're saying. If you dont it just makes you sound stupid.... thus people dont listen. It only takes a few seconds to read what you type.supraguru05 said:come on IJ just because i dont ever use spell check or grammer or read what i just typed doesnt mean you have to make fun of me :cry:

My VW Jetta TDI diesel rules. 4500 redline and plenty of torque. Its a full size 4 door with a massive trunk too.....

42cty/48+ hwy. I am very meticulous about measuring my fuel economy and this is very consistent. I have to drive it very hard with the AC on to get it below 42 MPG.

If I go 60mph I get 50+ MPG.

Suck it hybrids.

42cty/48+ hwy. I am very meticulous about measuring my fuel economy and this is very consistent. I have to drive it very hard with the AC on to get it below 42 MPG.

If I go 60mph I get 50+ MPG.

Suck it hybrids.

its my understanding that the diesel engine was originaly designed to burn vegitable oil...only after the inventor died and developers backed by oil comapnies took over, was "diesel" fuel developed for their engine.

You cant be serious?F_T_F said:a few seconds that can be spent doing other things.

SG05: You know about Diesels but as Tiss noted it makes it hard to take your posts seriously when you misspell it, I wasn't making fun of you.

I was always told the reason diesels' where so noisy was that they keep the tolerances loose...

GM tightened em up and they started to not sound like a box of rocks...

Supposedly.

Banks has been taking diesels pretty damn far with redlines over 6K on the GM engine with large turbos...

Sounds like a fun ride, the only issue is all the black smoke would piss off everyone (including the officer that thinks you're doing it intentionally). One of the guys at Carcraft wanted to stuff one of these engines in a old muscle car, tub it and drag race it. Would be a fun project...

GM tightened em up and they started to not sound like a box of rocks...

Supposedly.

Banks has been taking diesels pretty damn far with redlines over 6K on the GM engine with large turbos...

Sounds like a fun ride, the only issue is all the black smoke would piss off everyone (including the officer that thinks you're doing it intentionally). One of the guys at Carcraft wanted to stuff one of these engines in a old muscle car, tub it and drag race it. Would be a fun project...

The reasons that it is hard to rev a diesel very fast is that there is no way to advance the ignition. The fuel air mixture is only going to ignite when its going to ignite.

This leads to the long stroke, since you dont have to worry about piston speeds. This leads to the massive torque.

This leads to the long stroke, since you dont have to worry about piston speeds. This leads to the massive torque.

the black smoke come's from alot of fuel.all you do is run more boost to clear it up.i have a dodge ram with a cummin's in it.it's pretty funny how fast a 7000lb truck get's moving with all the torque.i go on the forum's and read alot of the thing's people are doing with them.they hold the wastegate shut and run 35 psi on the stock charger(stock is almost 20).they use one turbo to spool up another.they run the turbo outlet to the inlet of a bigger charger.there's a good number of guy's making over 500 whp +1100flbs

the stock head gasket blow's around 50-60 psi of boost.

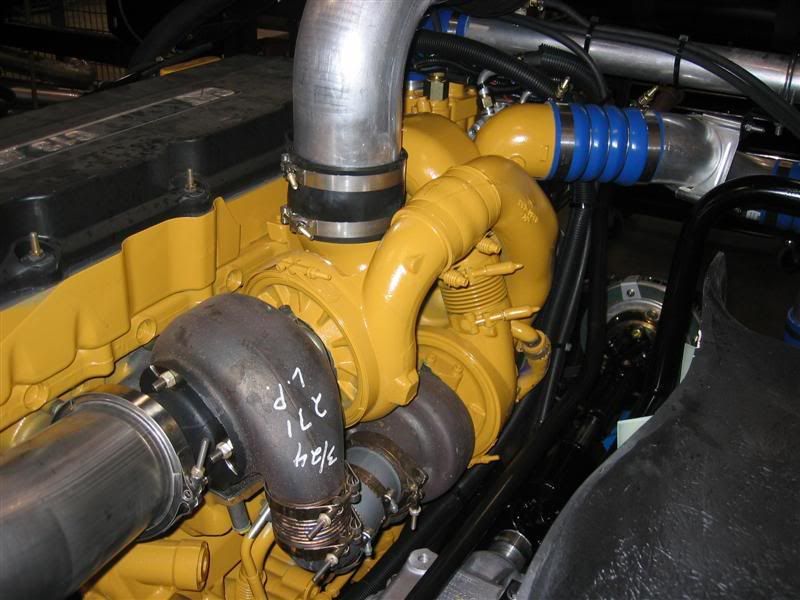

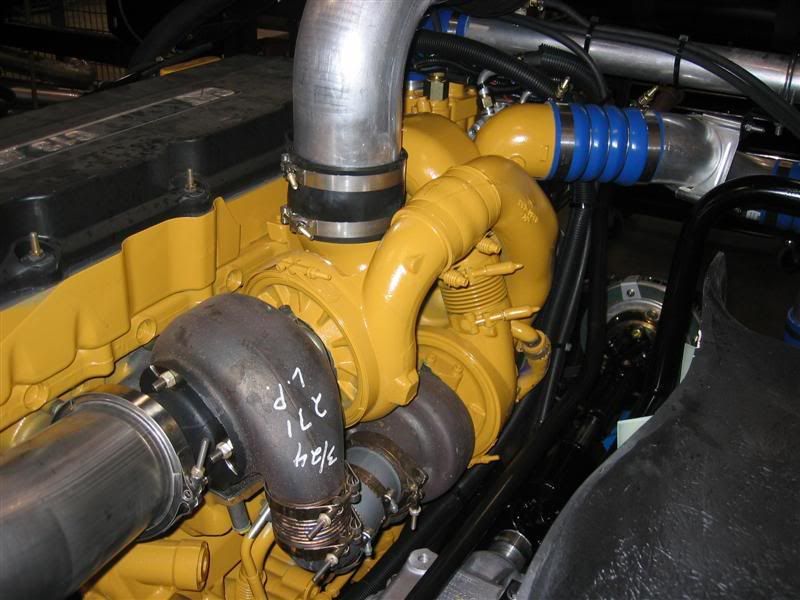

i'm still kinda new to it though and have very few mods.these pic's are from dtr member 5.9 excursion

[/QUOTE]

[/QUOTE]

the stock head gasket blow's around 50-60 psi of boost.

i'm still kinda new to it though and have very few mods.these pic's are from dtr member 5.9 excursion

Last edited:

omgwtfbbq?tsuper92 said:the black smoke come's from alot of fuel.all you do is run more boost to clear it up.i have a dodge ram with a cummin's in it.it's pretty funny how fast a 7000lb truck get's moving with all the torque.i go on the forum's and read alot of the thing's people are doing with them.they hold the wastegate shut and run 35 psi on the stock charger(stock is almost 20).they use one turbo to spool up another.they run the turbo outlet to the inlet of a bigger charger.there's a good number of guy's making over 500 whp +1100flbs

the stock head gasket blow's around 50-60 psi of boost.

i'm still kinda new to it though and have very few mods.these pic's are from dtr member 5.9 excursion

Awesome replies guys, read through every single one because I honestly didn't expect this thread to generate as much comment as it did, but i'm pleased of what i'm reading... makes you understand a lot.

Who said Supramaniac's weren't Diesel Savvy!.

Who said Supramaniac's weren't Diesel Savvy!.

That series turbo setup comes factory on a lot of the newer CAT diesels. On the motorhomes I work on, they have problems keeping the charge air cooler couplers on. The fix is to install a second t-bolt spring clamp to all connections. They run up to 50psi from the factory.

Last edited:

Tsuper, you bastard! nice compound setup. i notice its an Aurora setup, very nice! that turbo on the manifold is a stocker or at least a holset isnt it? is it an HX or a later HY or what? the secondary turbo looks something like a 4088 or something.

i also have a 1997 Ram 2500, Std cab long box. 12valve and 47RE, bpu mods, about 37psi, modded Ppump and such. EGT's stay under 1200* too.

The noise Diesels make is due to the combustion event. its not Uncontrolled, its a "fast" moving flame front percussiong off the cylinder walls. its Fast but slower than a gasoline engine that is pre-igniting or knocking. on a direct injection motor, the combustion event happens all at once rather than propagating from the center-outward like spark ign. also, a gallon of diesel fuel has a higher BTU content than a gallon of gas (that means more energy to be converted into motion )

)

Diesels run (At least on the cummins ISB series) 16.8-17.5 static CR's plus 18-20psi stock boost. i run 37psi on mine after the upgrades.

Diesels are engineered with VERY similar principles that the JZ series shares, as well as the G54B from the STar/quest and the 7M's even share some design characteristics. The Cummins ISB's generally look very similar to the JZ, oil pump mounting/design, water pump mounting design, head gaskets, head bolts, block design, etc. the only difference is the cam in block instead of OHC. thats why i love the ISB's and JZ's.

for the Record, the 6.5L motor found in the GM's was a Detroit Diesel engine and didnt suck balls. the 6.2L was a precursor to the 6.5L and was also very sturdy and reliable but low on power... thats why there were more 454's sold to private people who didnt own farms. the Military contracted to use the 6.2L powered K5 blazers for YEARS... easy to work on, easy to fix, easy to run. Even when the H1 came out, they ran Detroit Diesel built 6.5L turbo diesels with Standyne Rotary injection pumps. these IP's have tighter tolerances and more sensative to "drier" fuels. so 6.5's running at air strips and in the military have to have IP's rebuilt/replaced often or simply mix 30weight oil with the Jet fuel. when they wear, they cant purge air and stall or hard-start. this is why i love the Bosch P-pumps=bullet proof and can run on almost ANYTHING! the GM diesel that DID suck was the 350 diesel found in G-bodies in the early 80's. it was the only engine GM ever produced to have a 100% failure rate... it was a gasoline engine converted to diesel operation.

Diesel Can rev, look at the Audi TDI R10 race car... V12, SILENT, Powerful, Efficient and whoops EVERYTHING'S Ass in the LMP class. they won... what, 6 Lemans events in a row? 2000-2006 right? when the TDI car came first came out, it went longer between pit stops and made more power. they changed the rules just to exclude and crack down on how well the TDI outshown the Petrol cars. that V12 Also revs pretty high, not 13,000 rpm, but high. also, the V10 in the TDI Toureg revs quite high, is virtually silent and makes great power. lets not forget the Vemori-powered Jeep Liberty's. bad ass vehicles! oh, and the Bluetec-powered Mercedes, they rev over 3000rpm too.

even my 12valve will rev to 5400 before it spits rods out the oil pan. Sheid diesel builds their 12valves to run that hard, but not for long. however, 3600 is where the valves float; upgrade them. 4100 is a harmonic imbalance so you cant sustain that RPM, but otherwise, 4000rpm is a typical redline for modded 5.9's.

the reasons why big diesels dont rev high (in medium class trucks)

thats why the Cummins is a MAN motor! the Isuzu engineered 6.6 dirtymax is still akin to gas motors... which is why it can rev higher. the crank on our Cummins ISB's weighs something like 150lbs ALONE. the Rods and pistons are pretty damn stout too, as you can see.

also, NEWER diesels do have "throttle plates" but not for Throttling engine speed. they are to assist in engine braking. The 6.0 and 6.4 Power strokes have these plates as well as the Duramaxs. they suffer from pretty significant compressor surge problems. or "turbo bark" as they call it in the diesel crowd.

as far as making direct injection diesels quieter, they spaced the injection events and made them multistage, as mentioned earlier. its a couple smaller squirts to start combustion and then the rest of the fuel volume for the maxiumum power asked at that time. it brings the cylinder pressure up more gradually compared to the DI of the past. similar to how IDI motors were a little quieter to the DI motors... however, IDI requires the use of glow plugs, and real diesels dont use glow plugs; they use Intake Heating grids. Eat that "wait to start" and "glow plug" lights!

btw, diesels will run anywhere from stoich (idle) to rich (WOT-prespool). on my truck, its full mechanical. absolutely ZERO electronic engine management. my fuel control is mechanical, pre boost and boost fueling. at throttle tip-in and under 6psi, my truck smokes like a FREIGHT train. its Fun as hell, scares/pisses people off and just looks bad ass. under boost, my truck is tuned pretty well and only gives up a grayish haze. its not lean but its not over-fueled. smoke means lost power and unburned diesel, obviously. oh, and just so you guys know, the injection pump plunger volume is 88mm/3. also, as a reference, a walbro 255 is WAY Over kill for us to use as an intank lift pump.

heres something for your consideration... btw, try shifting your 7M-powered car at 3000rpm. listen closely to how much they sound just like a Cummins 12valve.

http://www.youtube.com/watch?v=NuF9pOcR1Qk

http://www.youtube.com/watch?v=ox4cwo0bk1U

i also have a 1997 Ram 2500, Std cab long box. 12valve and 47RE, bpu mods, about 37psi, modded Ppump and such. EGT's stay under 1200* too.

The noise Diesels make is due to the combustion event. its not Uncontrolled, its a "fast" moving flame front percussiong off the cylinder walls. its Fast but slower than a gasoline engine that is pre-igniting or knocking. on a direct injection motor, the combustion event happens all at once rather than propagating from the center-outward like spark ign. also, a gallon of diesel fuel has a higher BTU content than a gallon of gas (that means more energy to be converted into motion

Diesels run (At least on the cummins ISB series) 16.8-17.5 static CR's plus 18-20psi stock boost. i run 37psi on mine after the upgrades.

Diesels are engineered with VERY similar principles that the JZ series shares, as well as the G54B from the STar/quest and the 7M's even share some design characteristics. The Cummins ISB's generally look very similar to the JZ, oil pump mounting/design, water pump mounting design, head gaskets, head bolts, block design, etc. the only difference is the cam in block instead of OHC. thats why i love the ISB's and JZ's.

for the Record, the 6.5L motor found in the GM's was a Detroit Diesel engine and didnt suck balls. the 6.2L was a precursor to the 6.5L and was also very sturdy and reliable but low on power... thats why there were more 454's sold to private people who didnt own farms. the Military contracted to use the 6.2L powered K5 blazers for YEARS... easy to work on, easy to fix, easy to run. Even when the H1 came out, they ran Detroit Diesel built 6.5L turbo diesels with Standyne Rotary injection pumps. these IP's have tighter tolerances and more sensative to "drier" fuels. so 6.5's running at air strips and in the military have to have IP's rebuilt/replaced often or simply mix 30weight oil with the Jet fuel. when they wear, they cant purge air and stall or hard-start. this is why i love the Bosch P-pumps=bullet proof and can run on almost ANYTHING! the GM diesel that DID suck was the 350 diesel found in G-bodies in the early 80's. it was the only engine GM ever produced to have a 100% failure rate... it was a gasoline engine converted to diesel operation.

Diesel Can rev, look at the Audi TDI R10 race car... V12, SILENT, Powerful, Efficient and whoops EVERYTHING'S Ass in the LMP class. they won... what, 6 Lemans events in a row? 2000-2006 right? when the TDI car came first came out, it went longer between pit stops and made more power. they changed the rules just to exclude and crack down on how well the TDI outshown the Petrol cars. that V12 Also revs pretty high, not 13,000 rpm, but high. also, the V10 in the TDI Toureg revs quite high, is virtually silent and makes great power. lets not forget the Vemori-powered Jeep Liberty's. bad ass vehicles! oh, and the Bluetec-powered Mercedes, they rev over 3000rpm too.

even my 12valve will rev to 5400 before it spits rods out the oil pan. Sheid diesel builds their 12valves to run that hard, but not for long. however, 3600 is where the valves float; upgrade them. 4100 is a harmonic imbalance so you cant sustain that RPM, but otherwise, 4000rpm is a typical redline for modded 5.9's.

the reasons why big diesels dont rev high (in medium class trucks)

thats why the Cummins is a MAN motor! the Isuzu engineered 6.6 dirtymax is still akin to gas motors... which is why it can rev higher. the crank on our Cummins ISB's weighs something like 150lbs ALONE. the Rods and pistons are pretty damn stout too, as you can see.

also, NEWER diesels do have "throttle plates" but not for Throttling engine speed. they are to assist in engine braking. The 6.0 and 6.4 Power strokes have these plates as well as the Duramaxs. they suffer from pretty significant compressor surge problems. or "turbo bark" as they call it in the diesel crowd.

as far as making direct injection diesels quieter, they spaced the injection events and made them multistage, as mentioned earlier. its a couple smaller squirts to start combustion and then the rest of the fuel volume for the maxiumum power asked at that time. it brings the cylinder pressure up more gradually compared to the DI of the past. similar to how IDI motors were a little quieter to the DI motors... however, IDI requires the use of glow plugs, and real diesels dont use glow plugs; they use Intake Heating grids. Eat that "wait to start" and "glow plug" lights!

btw, diesels will run anywhere from stoich (idle) to rich (WOT-prespool). on my truck, its full mechanical. absolutely ZERO electronic engine management. my fuel control is mechanical, pre boost and boost fueling. at throttle tip-in and under 6psi, my truck smokes like a FREIGHT train. its Fun as hell, scares/pisses people off and just looks bad ass. under boost, my truck is tuned pretty well and only gives up a grayish haze. its not lean but its not over-fueled. smoke means lost power and unburned diesel, obviously. oh, and just so you guys know, the injection pump plunger volume is 88mm/3. also, as a reference, a walbro 255 is WAY Over kill for us to use as an intank lift pump.

heres something for your consideration... btw, try shifting your 7M-powered car at 3000rpm. listen closely to how much they sound just like a Cummins 12valve.

http://www.youtube.com/watch?v=NuF9pOcR1Qk

http://www.youtube.com/watch?v=ox4cwo0bk1U

Last edited: