Update: NOT Going 1MM oversize!

Hey Team!

The Game Plan:

1. Finalize Hardness Testing Using My Scleroscope. (looking good so far!)

("Scleroscope" <edit IJ>)

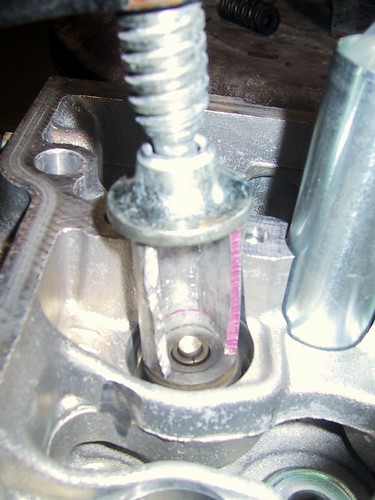

2. Dissasemeble the Head Using The Socket Magnet Method

Send off to machine shop!

3. Have my Machinist check out the head for cracks, ect, and at the same time clean up and prep it for a MLS gasket.

3. Check Valve Guides and make sure they're at TSRM Specs and as necessary replace and have the guide posts reamed to factory clearances.

4. Have My Machinist Gasket Match Port My Head on the intake side.

5. Have the valve seats grinded and also have the valves grinded. Replace valves as necessary if they aren't straight ect.

6. Pressure Test!

Bring her home!

7. Using the PCV pipe tool or a valve spring compressor reassemble the head with new comp cam springs and valve seals. With Valve Grind Lube on the valve grinds and assembly lube on the valve seals.

8. Upgrade the exhaust side hardware to 7/16's studs using the driftmotion ftw kit.

9. DONE!

Any other suggestions?

Does anyone have suggestions for the valve seal pliers? I remember there was a snap on tool that was like twenty bux.

What do you guys think?!

I'm open to constructive and deconstructive criticism and don't get butt hurt like 65% of you mofo's when I rain on your parades.

If you have NFI; Feel Free to Post.

Just Realize my center scroll on my mouse will work overtime.

Thanks!

Sumeet

Hey Team!

The Game Plan:

1. Finalize Hardness Testing Using My Scleroscope. (looking good so far!)

("Scleroscope" <edit IJ>)

2. Dissasemeble the Head Using The Socket Magnet Method

Send off to machine shop!

3. Have my Machinist check out the head for cracks, ect, and at the same time clean up and prep it for a MLS gasket.

3. Check Valve Guides and make sure they're at TSRM Specs and as necessary replace and have the guide posts reamed to factory clearances.

4. Have My Machinist Gasket Match Port My Head on the intake side.

5. Have the valve seats grinded and also have the valves grinded. Replace valves as necessary if they aren't straight ect.

6. Pressure Test!

Bring her home!

7. Using the PCV pipe tool or a valve spring compressor reassemble the head with new comp cam springs and valve seals. With Valve Grind Lube on the valve grinds and assembly lube on the valve seals.

8. Upgrade the exhaust side hardware to 7/16's studs using the driftmotion ftw kit.

9. DONE!

Any other suggestions?

Does anyone have suggestions for the valve seal pliers? I remember there was a snap on tool that was like twenty bux.

What do you guys think?!

I'm open to constructive and deconstructive criticism and don't get butt hurt like 65% of you mofo's when I rain on your parades.

If you have NFI; Feel Free to Post.

Just Realize my center scroll on my mouse will work overtime.

Thanks!

Sumeet

Last edited: