ok now that I have to start putting everything together excpet a mass amount of questions hahahahah.

ok well on too my first delima

I need to put the tranny back on the the engine both are out of the car disconected. Now I read the tsrm:

http://www.cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=MT&P=6

But alot of it doesn't make sense. So what do I All need to coat in greese and what kind of greese will work?

And where does the little fork(I think its called the realse fork) in there go or how do I install it properly???

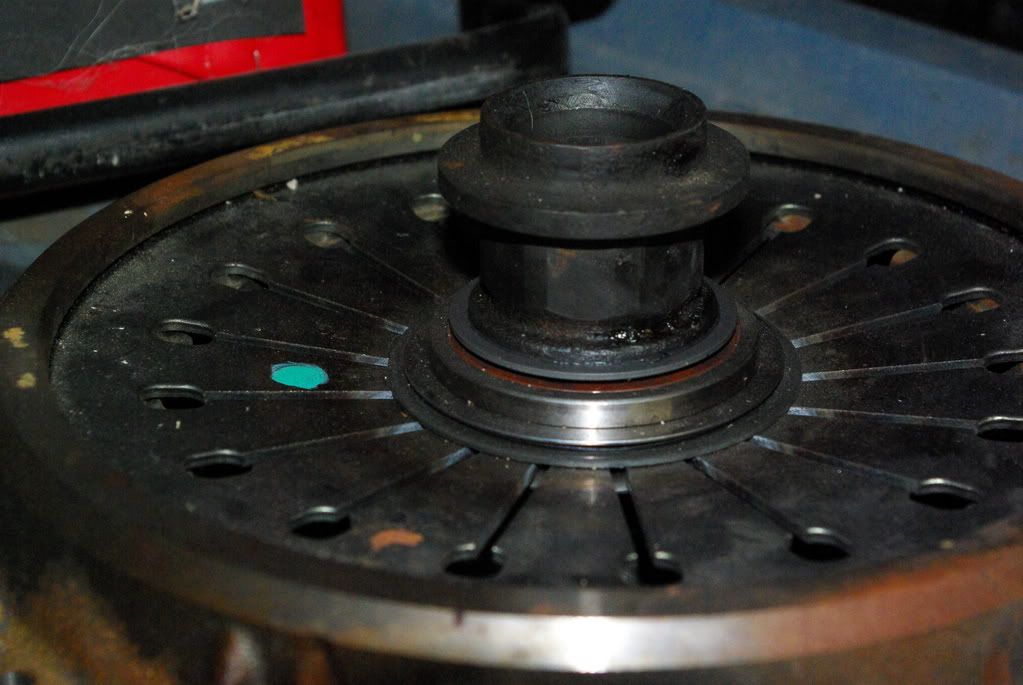

I need it too go on to this the pressure plate and clutch are on the engine already. so DO I just slide it on, greese what need to be greesed and put that fork somewhere?

HELP PLZ! lol:1zhelp: :aigo:

ok well on too my first delima

I need to put the tranny back on the the engine both are out of the car disconected. Now I read the tsrm:

http://www.cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=MT&P=6

But alot of it doesn't make sense. So what do I All need to coat in greese and what kind of greese will work?

And where does the little fork(I think its called the realse fork) in there go or how do I install it properly???

I need it too go on to this the pressure plate and clutch are on the engine already. so DO I just slide it on, greese what need to be greesed and put that fork somewhere?

HELP PLZ! lol:1zhelp: :aigo: