Continuing on with the cylinder head porting, I finished off the exhaust ports (did some more cleaning and radiused some sharp corners) Also did some combustion chamber work. Radiused the sharp squish area on the port sides of the chambers and removed the factory valve shrouding.

With doing this modification more of the valve will be used during intake and exhaust. Take note of how much more the vavles are exposed. I believe about 1 third more of each vavle is now being used.

I am lowering the compression ratio, but will be running an HKS 1.2mm MHG (which is thinner then stock) so hopefully I will retain close to stock c.r.

In the first 2 pictures I very carefully handled the MHG and placed it on the cylinder head to mark out where the new gasket will sit around the cylinder. Gives me a basic guide line to where my limits are to cut out material.

This time around I used more basic tools, just air powered angle drive with 3 different carbid cutting heads. a medium and small rose bud and 1 medium straight cut. You could get away with just using the small rose bud (just takes more time to remove material)

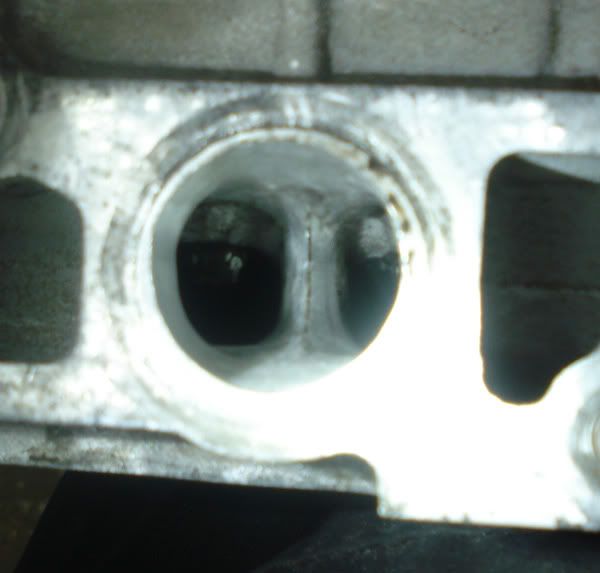

Picture of the stock combustion chamber

Starting to remove material on the first cylinder.

These last three pictures are fairly self explanitory.

This is the finished product after about 2.5 hours of work. Takes much less time to do this mod comparing to port work. All the valves where put into the head and I took a emery roll and texturize and smooth the chambers. Id give this mod a 4 out of 10 on the difficulty level. But GREAT CARE must be taken with enlarging the chamber, you do not want to go past the gasket area! Otherwise you will have a very large paper weight. I gave myself plenty of space not to cut too close to the gasket. (want to be safe here) If knock occurs the gasket wont be exposed as much, could prevent a BHG.