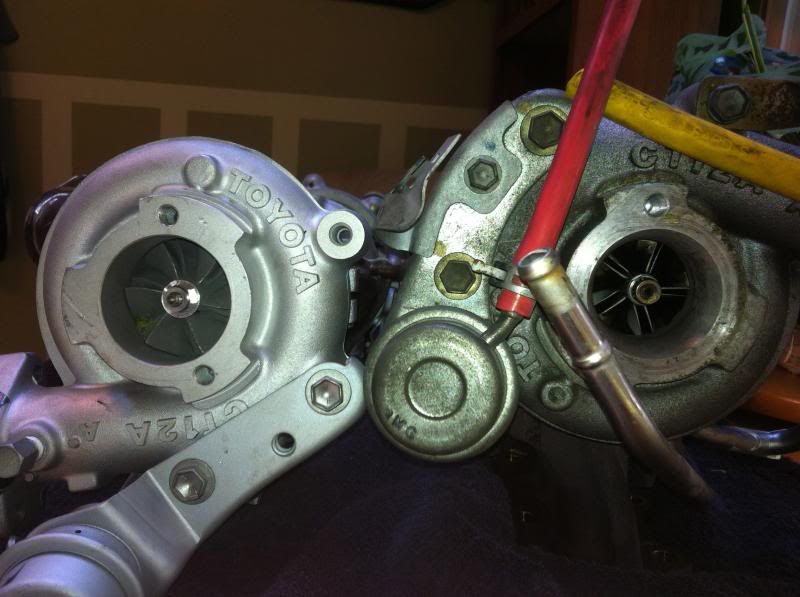

Yep! It was set at 14psi and it was a well built car before my buddy sold it. They're pretty neat up close.

You would need to keep the MA70 seatbelt buckles from your factory seats and replace your Celica buckles with them. The factory Celica rails where used. 3 out of 4 Celica paws are positioned horizontally to bolt to the floor, and the last paw (rear center) is positioned vertically. I thought that this last paw was going to cost me some welding time until I had removed the factory MA70 seats and discovered a seat belt rail that was bolted to the tranny tunnel, and that threaded bolt hole was located near the area where the vertically positioned paws will be. Score!

Starting off with the front paws, they needed to be turned in to the right position so that the rings are center-lined with their seat rails. Turning the paws to the right position is done by drilling out their the tack weld, so that the paws could pivot around their pins to be adjusted just like MA70 front paws, to later be modified to drop in to MA70 factory position. The ring holes for the bolts where widened with a step bit only to position the bolts a little further forward, because the two holes on the MA70 floor are a little more spaced apart than the Celica holes by a 1/4" or less. So modifying the rings in the paws wider and turning the oval holes in the floor to circles did the trick. After doing this and hammering the paws to curl to the curvature of the floor, they will bolt up with the OEM bolts. Once they are bolted down nice and tight you can then start working at the exterior rear corners.

The rear outside corners where next. I've purchased some 5/8" thich x 1.5" x 1' steel plate to modify as adapter plates. Note that the plates made for both the passenger rear outside paw and the driver side rear outside paw will be identical. I figured this out the hard way lol. Fist drill a hole for your OEM bolt to drive through freely. After making sure your front paws are straight and tight, bolt the plate to the ground and run the plate under the Celica rear outside paw and use a marker to circle your next bolt hole. Drill that spot, cut 1/4" away from the bolt hole and try it out. Now while using a aftermarket nut & bolt with a lock washer (make sure to buy high grade bolts that can withhold extra torque for added safety) nut & bolt one end of the steel plate to the paws (removing the front bolts will make this easier) then bolt one end of the plate on the existing MA70 seat floor hole. At this point with the 3 horizontal paws bolted down, your seat should be sturdy enough for you to get a first feel of the seat height and look. Then you can simply duplicate this adapter plate to bolt on the other seat.

The final paw. This one is a bit of a pain because it needs to be bolted to a threaded MA70 bolt hole that is vertically positioned and there is no other option than the seatbelt rail holes that are located on your tranny tunnel. Similar to the last step, nut & bolt the rest of your steel plate to the paw and line it up with the MA70 hole and mark your new hole. With the help of spacers positioned between the steel plate and the tranny tunnel you will need to purchase a longer bolt to replace the OEM one that was originally used to fashion the said seatbelt rail that is no longer needed. Reminder, the location of the threaded MA70 tranny bolt holes are not mirrored to the other side of the tunnel, meaning you cannot simply copy the plate (like in step 2) you've made for one seat and use it for the other seat. They will be different lengths. The best bet for spacers is to use sleeved and hatted bolts and to find steel tubing with the perfect ID & OD to cut to length. That would be the cleanest solution for a fast car with a heavier driver to help prevent failure without having to modify the inside rails to be directly bolted to the floor.

The seats costed me $100 for the pair at any yard, spent a few bucks on high rated stainless hardware and steel plates, not to mention a few drill bits... The Celica seats don't have lumbar or heat, however they weigh I believe ~34lbs each vs. the MA70's 74lbs drivers seat alone. I never had the chance to weigh the factory MA70 passenger seat. I can't really post a total weight loss figure but almost half of the weight is gone. This took me about 4 hours because of drilling time mostly. The only stiff problem with this is that your seat rails may not be exactly perpendicular to each other, causing a friction or a lot of resistance to the front and back sliding motion of your seats. Other than the wish of using adjustable sway bar end links as spacers to free the sliding resistance I am very happy with the swap.