car wont boost over 10psi?1jzgte

- Thread starter -AR-

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need some more details. So low you get 10 psi, and high you get 5psi? Running a tial external wastegate how did you hook up the vacuum lines to from the solonoid to the wastegate? Have you tried boosting with the Electronic boost controller off which should return to actuator and boost at the stock spring pressure that's in the tial wastegate? You may have it backwards so boost is cracking the wastegate wrong. How many sources go to the wastegate? Is the manifold sensor line that comes from the evc going to a source that will see vacuum meaning after the butterfly?

I have it Wastegate to solenoid to turbo. Ebc to T to intake manifold and fpr.I tried to wire it how they have it in the directions online. Evc? I'm new to Supras so learning. Will try to see what it does with the Ebc off..MA67SupraTurbo;1877218 said:Need some more details. So low you get 10 psi, and high you get 5psi? Running a tial external wastegate how did you hook up the vacuum lines to from the solonoid to the wastegate? Have you tried boosting with the Electronic boost controller off which should return to actuator and boost at the stock spring pressure that's in the tial wastegate? You may have it backwards so boost is cracking the wastegate wrong. How many sources go to the wastegate? Is the manifold sensor line that comes from the evc going to a source that will see vacuum meaning after the butterfly?

I think I went from bottom of Wastegate to solenoid if I remember correct.I'll confirm tonight when I get off.91Supra313;1877233 said:Which lines are run where on the wastegate from the EBC solenoid?

going to take some pics this weekendTurbo Habanero;1877344 said:Just take a bunch of pics and the guys will be able to tell if the vac is routed correctly

So where is the line that comes from the waste gate hooked up?

where is the line from the turbo housing hooked up? If those are not hooked up in the right area then the boost controller does nothing but look good.

where is the line from the turbo housing hooked up? If those are not hooked up in the right area then the boost controller does nothing but look good.

Line from the bottom/side of Wastegate goes around the shock tower to the Freddy box.then from the box to the turbo.previous owner wrote in and out on the box so I don't think I messed that up. I have to look up directions on how to use the controller..maybe I'm using it wrong? High ans loo boost knobs are turned all the way up but for whatever reason lot is 10 and hi is 5

i ran the vacuum a different way now...WG side to t going to turbo and solenoid in...then solenoid out to WG top...

now i get 10psi on hi and lo....i can use the other knob and it makes a difference in how boost comes in...but i still cant more than 10 psi...

going to change the spring next...

now i get 10psi on hi and lo....i can use the other knob and it makes a difference in how boost comes in...but i still cant more than 10 psi...

going to change the spring next...

This sounds correct!-AR-;1879077 said:i ran the vacuum a different way now...WG side to t going to turbo and solenoid in...then solenoid out to WG top...

now i get 10psi on hi and lo....i can use the other knob and it makes a difference in how boost comes in...but i still cant more than 10 psi...

going to change the spring next...

The side of the wastegate is what actually cracks the valve by pushing on the diaphragm during boost. Without that, the spring up in the top of the wastegate (opposite the mounting bolts) keeps it closed until you hit whatever psi. Most setups want a turbo source to the side, which would crack it open once boost overpowers the spring, but the greddy will send boost to the OTHER side of the wastegate (the top/hat) to counter and help the spring fight it, keeping it closed more, until a higher boost is hit. So...

1.Do not have any lines from the FPR going to the Wastegate. That would put vacuum to it, that needs to go to the EBC with one port for reference.(simple)

2.Take the line from close to the turbo, and connect it to the side of the wastegate, with a Tee to the "IN" on the EBC. Even if you burned your ebc, this is the only line you would need, just from turbo boost source, to the side of the wastegate. This is what takes the pressure, and fights the spring up in the top "hat" of the wastegate, this is all you would need to run whatever psi spring you had. But you need to Tee off this line to the 'In' of the EBC.

3.Now take the line from the top "hat" and connect that to the "Out" on the EVC, (EVC is the same as EBC, but I'm tired of saying EBC).

Now let's think about what is happening. Forget about the line to the FPR, it's a reference for the EVC to know what boost is being made. Forget it. Imagine you connecting the lines that went I and O of the EVC together, and you pinched the line instead of using the EVC. If you pinched it shut like normal "off mode," only the side of the wastegate would see pressure, becuase you Tee'd it off from turbo to the side, and ran a line to where your finger is now pinching. The car is on the dyno and the let's say 10 psi spring feels, about 10psi of boost and opens. But you want more boost don't ya, greedy bastard, so let's help that 10 psi spring out, by putting pressure through the "top/hat" (by un-pinching the line) and letting boost go OUT. Look at that, the 10 psi spring is being assisted by your stepper motor like fingers, and voila. You hit 19psi and blew an IC pipe, stupid Jubilee fittings.

Some evc's use different methods and control what the spring see's, there's more to it but this is a good way to think of it so you aren't just guessing on what port does what and why.

Lastly inspect you wastegate's diaphragm for tears, and try to push the valve with your thumbs, you should barely or not be able to move it. A good target spring is half of your total expected psi. So if you max at 20, grab a 10 psi spring. (or grab a 20 psi one and forget about boost controller

Going to bed, I can't imagine the anticipation that must be killing you! Be patient!

-Steve-

Last edited:

MA67SupraTurbo;1879140 said:This sounds correct!

The side of the wastegate is what actually cracks the valve by pushing on the diaphragm during boost. Without that, the spring up in the top of the wastegate (opposite the mounting bolts) keeps it closed until you hit whatever psi. Most setups want a turbo source to the side, which would crack it open once boost overpowers the spring, but the greddy will send boost to the OTHER side of the wastegate (the top/hat) to counter and help the spring fight it, keeping it closed more, until a higher boost is hit. So...

1.Do not have any lines from the FPR going to the Wastegate. That would put vacuum to it, that needs to go to the EBC with one port for reference.(simple)

2.Take the line from close to the turbo, and connect it to the side of the wastegate, with a Tee to the "IN" on the EBC. Even burned your ebc, this is the only line you would need, just from turbo boost source, to the side of the wastegate. This is what takes the pressure, and fights the spring up in the top "hat" of the wastegate, this would all you would need to run whatever psi spring you had. But you need to Tee off this line to the 'In' of the EBC.

3.Now take the line from the top "hat" and connect that to the "Out" on the EVC, (same as EBC, but I'm tired of saying EBC).

Now let's think about what is happening. Forget about the line to the FPR, it's a reference for the EBC to know what boost is being made. Forget it. Imagine you connecting the lines that went I and O of the EVC together, and you pinched the line instead of using the EVC. If you pinched it shut like normal "off mode," only the side of the wastegate would see pressure, becuase you Tee'd it off from turbo to the side, and ran a line to where your ringer is now pinching. The car is on the dyno and the let's say 10 psi spring feels, 10psi and opens. But you want more boost don't ya, greedy bastard, so let's help that 10 psi spring out, by putting pressure through the "top/hat" by un-pinching the line and letting boost OUT. Look at that, the 10 psi spring is being assisted by your stepper motor like fingers, and voila. You hit 19psi and blew an IC pipe, stupid Jubilee fittings.

Some evc's use different methods and control what the spring see's, there's more to it but this is a good way to think of it so you aren't just guessing on what port does what and why.

Lastly inspect you wastegate's diaphragm for tears, and try to push the valve with your thumbs, you should barely or not be able to move it. A good target spring is half of your total expected psi. So if you max at 20, grab a 10 psi spring. (or grab a 20 psi one and forget about boost controller, j/k) I had trouble building boost in an MK2 and there was a piece of FOD that wouldn't let the wastegate shut. (one in a million chance) But sounds like you have it correct if FPR line is right.

Going to bed, I can't imagine the anticipation that must be killing you! Be patient!

-Steve-

so in short...i ran the vacuum right now and your saying on the filter side withe vacuum going to the box from the fpr and IM, change this and make it filter to IM and run the fpr off IM like it was originally?

I have no idea what you mean by filter, whether it be the intake filter or the small filter on the lines to the evc. The only reason for these filters is to prevent crap from going into the boost controller fouling it up.-AR-;1879199 said:so in short...i ran the vacuum right now and your saying on the filter side withe vacuum going to the box from the fpr and IM, change this and make it filter to IM and run the fpr off IM like it was originally?

Take the line going from the FPR to mani, and Tee it on the part of the evc that only has one port. May be labled "B" but not to the In/Out box, and not to any wastegate port.

If you did that and still only received 10 psi something is really wrong, and you very well could have built as much boost as the turbo would make. Inspect wastegate Diaphragm.-AR-;1879243 said:so went from turbo to top of WG...10psi..so its the spring..going to change it this weekend..

I wish you would explain your target boost and take your time to proof read your post, so you can be better helped. Stay patient. It will be worth it.

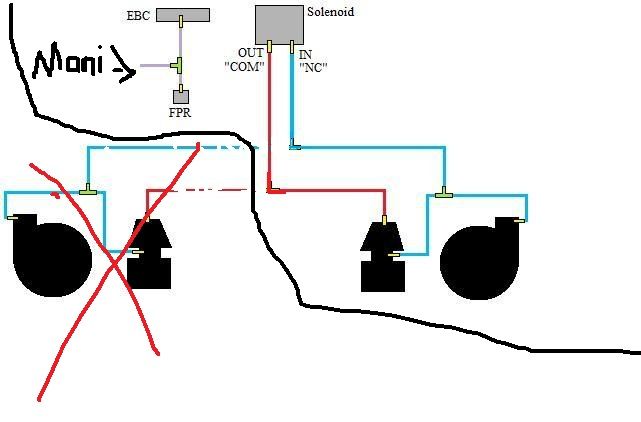

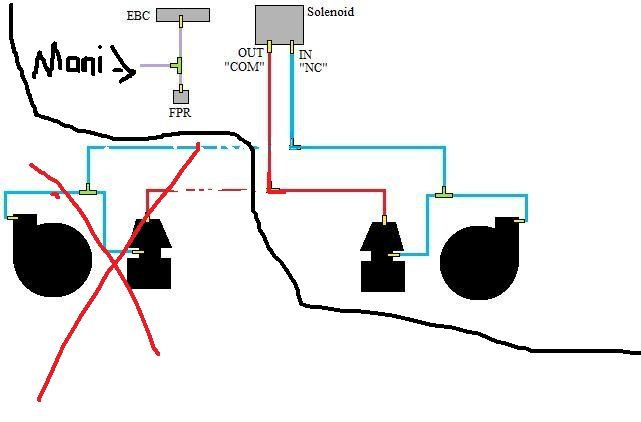

Here's a pic I put in paint to fix the twin setup, just ignore the bottom left and get an idea of how the fpr/mani goes.

http://i378.photobucket.com/albums/oo228/XXsodasipperXX/HoseSetupForTT.jpg

Last edited: