figgie said:funny thing it is not the Air Force reg. It is an FAA reg. The Air Force follows laws also

did you read that NASA link at the top of this page someone posted?

kinda interesting... what do you get from that?

figgie said:funny thing it is not the Air Force reg. It is an FAA reg. The Air Force follows laws also

IHI-RHC7 said:Conductivity: Crimp

Cleanlyness: Solder

IHI-RHC7 said:Conductivity: Crimp

Cleanlyness: Solder

supra90turbo said:

That is a good reason there not to use it on an aircraft. It can break easily.some chemists page said:Gold is also the most ductile of metals and can been stretched or extruded into very fine wire without breaking. Lead and tin are amongst the least ductile of metals.

from the same dudes page said:electrical conductivity: silver > copper > gold > aluminium > magnesium > zinc > iron > tin > chromium > lead.

mattjk said:Both solder and crimp is going to work fine in a car, what really matters is the person doing the job. Is he going to make a cold solder joint, or crimp too hard at the end and cut the wire off?

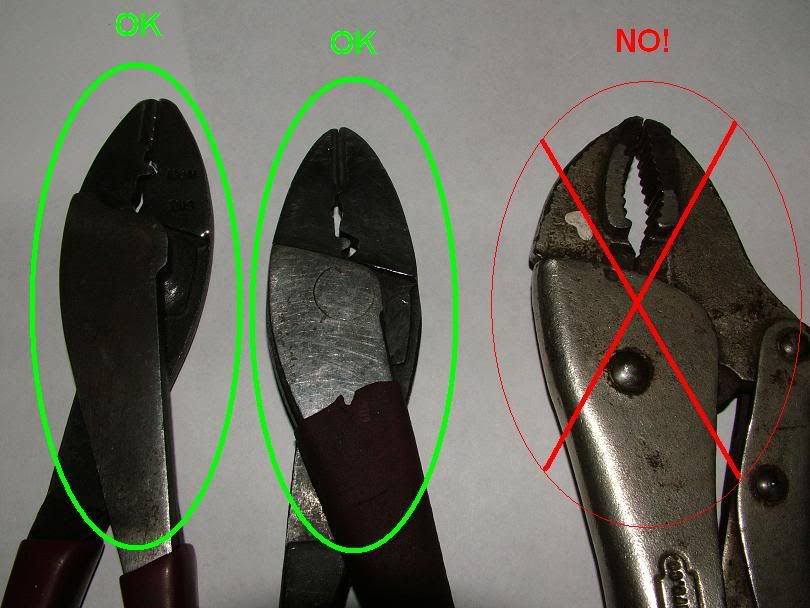

bigaaron said:That was not done with the proper crimp tool. Don't use pliers to crimp butt connectors.

{bigassimage}

:biglaugh: