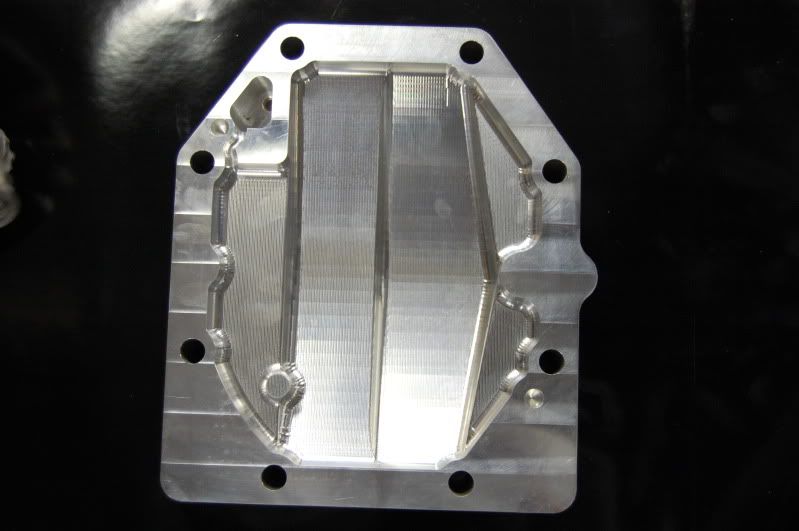

Enraged;1452418 said:the interior contours look like they were finished with a small ballmill, so I doubt the covers could be priced lower while still turning a decent profit. if you think you can do it, by all means, give it a shot and let us know how much it will cost.

it's sad to see people assuming they could get it made for less and trashing the business for trying to make a profit. i dont make parts (aside from one-offs for myself) unless i will make money, my time isnt free.

:3d_frown: i wasn't trashing the business, merely stating that i prefer to CNC my own parts when i am competent/able to do so if the alternative is a bit too $$y for me.