L

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just came down to the house to check e-mail and couldn't resist posting this!

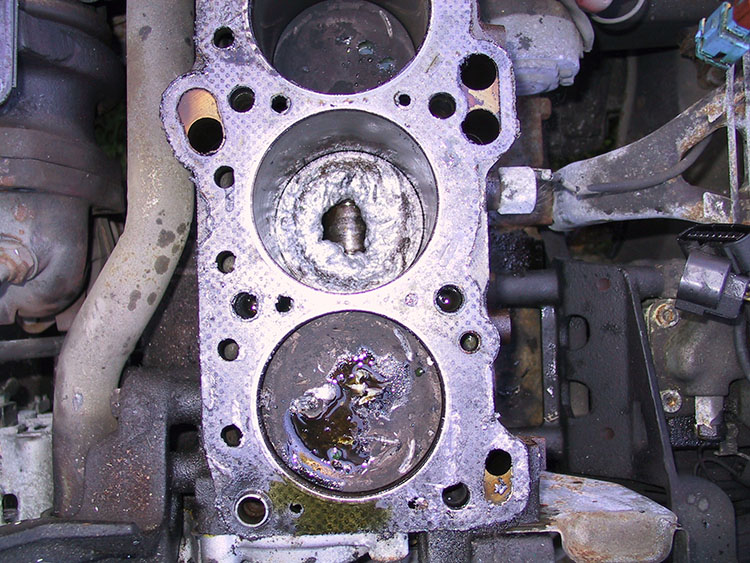

This is the result of Rod Knock + Crower injected BBChev+Broken ARP rod bolt!

I found quite a few of these parts on the road under the car!

The only parts with no damage in the entire motor were the Intake and the Water pump everything else was trashed!

This is the result of Rod Knock + Crower injected BBChev+Broken ARP rod bolt!

I found quite a few of these parts on the road under the car!

The only parts with no damage in the entire motor were the Intake and the Water pump everything else was trashed!

L

lanky189

Guest

Famous last words "What's that knocking sound?"

Or alt title "How to make a 7 litre Chev fit into a 4 litre can"

Thought you'd like em!

Or alt title "How to make a 7 litre Chev fit into a 4 litre can"

Thought you'd like em!

well here's mine

just in plural instead

stock = the stock gasket that blew.. previous owners thought 30ft lb was plenty

4mm crap one = crap quality, crap manufacturing.. fire rings weren't pre compressed therefore when i torqued it down it crushed the firerings and they burst open .. i thought originally it was due to standard bore hg and over size pistons that came above the block.. so smacked it to pieces

.. i thought originally it was due to standard bore hg and over size pistons that came above the block.. so smacked it to pieces

what it looked like first off = this is their gasket new... which turned into the following (damn good thing i didn't put that on the car i was intending)

2mm crap one = same company, crap quality, crap manufacturing... gee guess what.. fire rings burst open again... learnt my lesson that time

copper one = don't do it without o-rings and prepping the head and block.. didn't seal from day one... within a .2 mile drive i knew straight away it was gonna overheat.. it did.. compression came up awesome... no gasses in the water (yet) and no smoking and no mix of oil

this gasket when i took it off... seriously.. leaked from one end to the other of every single engine lubricant you can think of

oil into water, water into oil, water in cyl, cyl in cyl, cyl into water.. oh this was a great one LOL

and the one that's going on now... with arps.. torqued to ???? what should i torque it to? also considering it's 4mm.. lotsa metal to clamp hehe

so theres my broked parts

just in plural instead

stock = the stock gasket that blew.. previous owners thought 30ft lb was plenty

4mm crap one = crap quality, crap manufacturing.. fire rings weren't pre compressed therefore when i torqued it down it crushed the firerings and they burst open

what it looked like first off = this is their gasket new... which turned into the following (damn good thing i didn't put that on the car i was intending)

2mm crap one = same company, crap quality, crap manufacturing... gee guess what.. fire rings burst open again... learnt my lesson that time

copper one = don't do it without o-rings and prepping the head and block.. didn't seal from day one... within a .2 mile drive i knew straight away it was gonna overheat.. it did.. compression came up awesome... no gasses in the water (yet) and no smoking and no mix of oil

this gasket when i took it off... seriously.. leaked from one end to the other of every single engine lubricant you can think of

oil into water, water into oil, water in cyl, cyl in cyl, cyl into water.. oh this was a great one LOL

and the one that's going on now... with arps.. torqued to ???? what should i torque it to? also considering it's 4mm.. lotsa metal to clamp hehe

so theres my broked parts

eeeekk 4mm HG i see pain in your future  stock gasket (toyota brand only need apply), good tune, ARP studs to ARP torque specs, clean deck and smooth head with spray on hylomar = no probs mine has even survived a wastegate hose geting religious (holed)

stock gasket (toyota brand only need apply), good tune, ARP studs to ARP torque specs, clean deck and smooth head with spray on hylomar = no probs mine has even survived a wastegate hose geting religious (holed)

good luck but big gasket = big problems and decompressing using a gasket is a BIG no no, open up the chambers in the head if you must

good luck but big gasket = big problems and decompressing using a gasket is a BIG no no, open up the chambers in the head if you must

lol i would hate to think what my compression would be on a stock gasket when on 2mm it's 9.4:1 LOL

i love low compression thats just me, i love the "foot to floor... waiting.. holy #%# boost coming on" hehe...

thats just me, i love the "foot to floor... waiting.. holy #%# boost coming on" hehe...

with a 4mm hg my compression was 7.98:1 but now with another skim getting it to 17RA i suspect it'll be 8.0:1ish

my piece of arp paper says 82ft lbs but a few ppl have told me this won't be enuf?

i love low compression

with a 4mm hg my compression was 7.98:1 but now with another skim getting it to 17RA i suspect it'll be 8.0:1ish

my piece of arp paper says 82ft lbs but a few ppl have told me this won't be enuf?

L

lanky189

Guest

HEY YOU TWO.. GET A ROOM....this is off topic..take the tech talk to the tech section would ya!

sheesh.... ya try to run a section for off topic discussion.....

sheesh.... ya try to run a section for off topic discussion.....

This is what fell out when I pulled the cover off of a customers rear differential. I didn't get pictures of the Nitrous motor that one of the other guys pulled out of a 'vette. That was pretty amusing too.

Said it wouldn't move in 2 hi and made funny noises in 4hi, he was going to drive it to the shop but the service advisor talked him into waiting for a flatbed.

Complete piston removed from customers running car ....towed in with a "compresion problem" caused by driving thru flood & tow start manuel car

Rod from toyota 3vz camrey/windom cutomer lost power but still ruinning this bit of the rod was poking out of sump

Gudgin pin from a Honda prelude was running but ratting badly I gave it a "bit" of a rev engine went bang oil every were as this bit made a run for it

:burnout:

Nice 4G63BT there Jeff

Damn, that differential just took a shit on itself. Love that bent rod, it almost looks like it's supposed to be that way.

Damn I wish I had the pics left from my old Integra.... Hitting the 405 center divider just DESTROYED the front... But I doubt that would count anyhow. Well best to let go of painful memories. Not the car, I was sore for 5 days.

jeff, unfortunately, i see those things all the time.

i wish i had pics, but i had the beam of a rod separate completely from the big end. ive never EVER seen a failure like this. the big end was still on the crank journal, spun freely and the bearing was in perfect shape. the beam of the rod had been knocked thru the cylinder wall and broken into the water jacket. of course, ths was also on a 4G63 as well...

my friend was able to do the same thing in his 98 SP74 car when he had a WG failure. he raced a new STi and was reeling the guy in so hard that he blew the rod in 3rd gear, the engine died out and he had so much momentum, he pulled past the car and then fell back behind... made 560rwhp on pump gas at 18psi, no nitrous.

i wish i had pics, but i had the beam of a rod separate completely from the big end. ive never EVER seen a failure like this. the big end was still on the crank journal, spun freely and the bearing was in perfect shape. the beam of the rod had been knocked thru the cylinder wall and broken into the water jacket. of course, ths was also on a 4G63 as well...

my friend was able to do the same thing in his 98 SP74 car when he had a WG failure. he raced a new STi and was reeling the guy in so hard that he blew the rod in 3rd gear, the engine died out and he had so much momentum, he pulled past the car and then fell back behind... made 560rwhp on pump gas at 18psi, no nitrous.