Hey guys, I am putting my engine together now as we speak, and it seems like I have run into a bit of a problem, I have searched and found nothing, as I am torquing the studs onto the block not all of the studs are in equal amounts to one another, I was going to torque them to 80lbs per everyone on here recommended, I have been torquing them in steps 30 60 then 80. I haven't got any 80lbs because I saw this, and I am using the lube that came with the studs. All the holes wore clean before then went in, am I doing something wrong or is this normal?

ARP head stud problem

- Thread starter 7m2ner

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7m2ner;1242094 said:I am torquing the studs onto the block

Maybe he doesn't have the head on

Did you use a bottom tap?Standard style thread taps have a taper to make it easier to start the threads.

jetjock;1242177 said:Maybe he doesn't have the head on

True...just making sure. You never know around here

Yeah, that was my point. I put nothing past most of this crowd. It's the nature of the demographic...

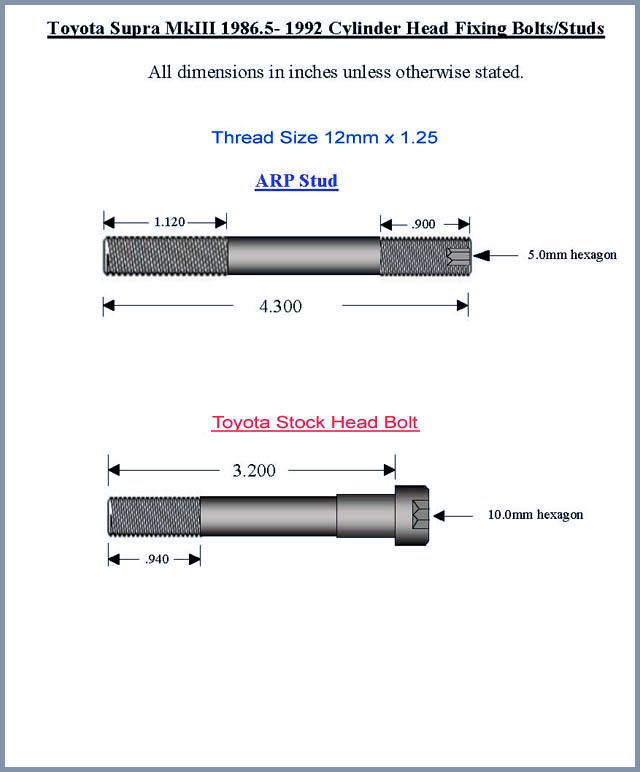

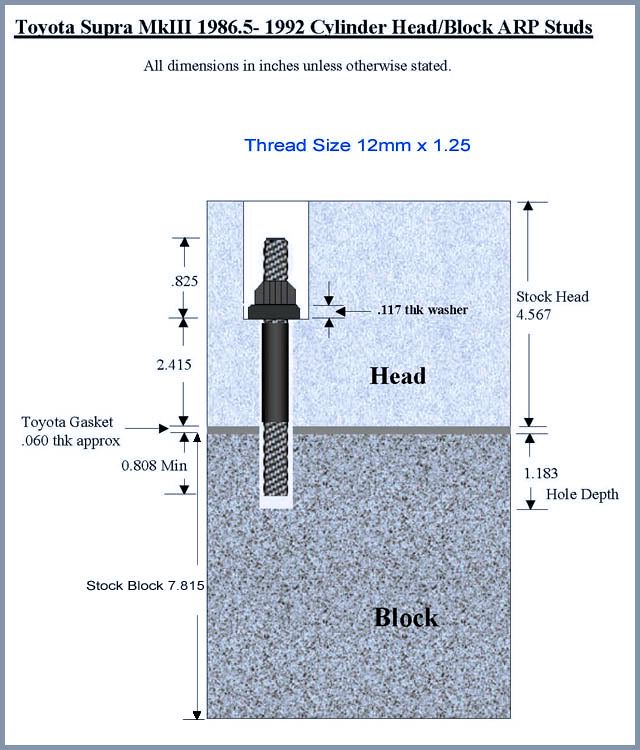

Bill UK's diagrams show why it's required to get them in all the way, but I think he need to make one of the stock headbolts to show just how little of the holre they use (about half is what I noticed).

First post was right, STOP!! As the studs bottom out, you can crack your block if you tighten them into the block. You say they're all uneven, so that means the threads need to be chased so the studs go in easily...

First post was right, STOP!! As the studs bottom out, you can crack your block if you tighten them into the block. You say they're all uneven, so that means the threads need to be chased so the studs go in easily...

Thanks guys for all the help, no I had not chases the holes, I am going to chase them now, and no I don't have the head on yet. One more quick question, so the studs are only finger tight in the block, they do not get torqued down? only the nuts?

That is correct...studs finger tight, nuts torqued to 80 ft/lbs using moly (ARP spec). Multiple passes in the TSRM pattern.

One thing often missed torquing on a head...setting proper pre-load:

One thing often missed torquing on a head...setting proper pre-load:

ARP said:The friction factor changes from one application to the next. That is, the friction is at its highest value when the fastener is first tightened. Each additional time the fastener is torqued and loosened, this value gets smaller. Eventually the friction levels out and becomes constant for all following repetitions. Therefore, new fasteners should be tightened and loosened through several cycles before applying final torque. The number of times depends on the lubricant. For all situations where ARP lubricants are used, five cycles are required before final torquing.

LOLing at this thread

Damn that much be a good 5mm InHex socket he's using to torque em to 80 ft/lbs! :aigo:

Damn that much be a good 5mm InHex socket he's using to torque em to 80 ft/lbs! :aigo:

^ Lmao. I was thinking the same thing.

I knew it. It's tough thinking on that level though....gives me a headache

I knew it. It's tough thinking on that level though....gives me a headache

jdub;1242253 said:That is correct...studs finger tight, nuts torqued to 80 ft/lbs using moly. Multiple passes in the TSRM pattern.

One thing often missed torquing on a head...setting proper pre-load:

two things...

what tq value do you go to before loosening & re torquing? And the quote says on NEW hardware, why? i understood it to be the friction between the two surfaces. If they are reused, the same pre-load technique should apply, right/wrong?

I take them up to 70 ft/lbs 1st 2 cycles, 75 ft/lbs 2nd 2 cycles, 80 ft/lbs final torque.

I pre-load regardless if new or used.

I pre-load regardless if new or used.

so is that heat cycles or before you even start the motor and you just torque break loose torque and so on?

hvyman;1242448 said:so is that heat cycles or before you even start the motor and you just torque break loose torque and so on?

Stone cold block never start the motor. See this thread it has great info on the subject.

You're burnishing the threads, that's why if they're used they're already broken in and will torque fine. I'm sure this accounts for MOST of the cases of the studs loosening up and needing a retorque.

I wasn't able to do quite finger tight in my block (that and my hands where tired as hell from chasing the threads... they where pretty damn bad), so I used an allen key to get them all the way in easily. You'll know when they bottom out (as they should).

I wasn't able to do quite finger tight in my block (that and my hands where tired as hell from chasing the threads... they where pretty damn bad), so I used an allen key to get them all the way in easily. You'll know when they bottom out (as they should).

Well thanks again to all for the help, today I spent almost the whole day running around town to find the rite size tap, figures it would be the last store after going to about 15 stores. So i barley had any time to work on it today but I got 3 threads done.