I don’t mean to sound like a jerk to anyone, but I’d recommend ignoring the various torque figures quoted by others. I’ve used ARP head bolts or studs for virtually every car I’ve owned in the last fifteen years, and my personal experience has led me to four “personal rules” when using ARP head bolts or studs:

1: Chase the threads using a good quality thread chaser.

2: Use ARP’s torque figures, not what other people insist is better.

3: If at all possible, use ARP’s moly lube, not 30WT engine oil.

4: Don’t just lube the threads; lube both sides of the washers as well, as this will help you get a torque reading that’s both more consistent and more accurate.

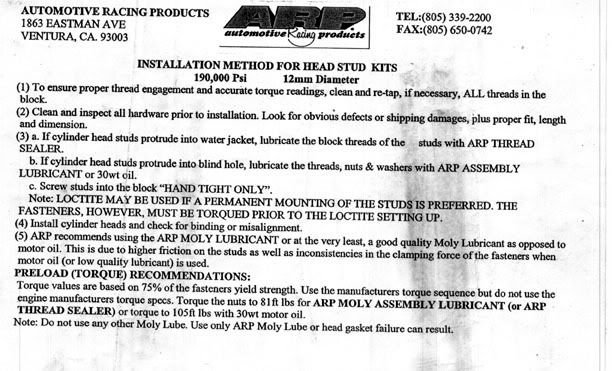

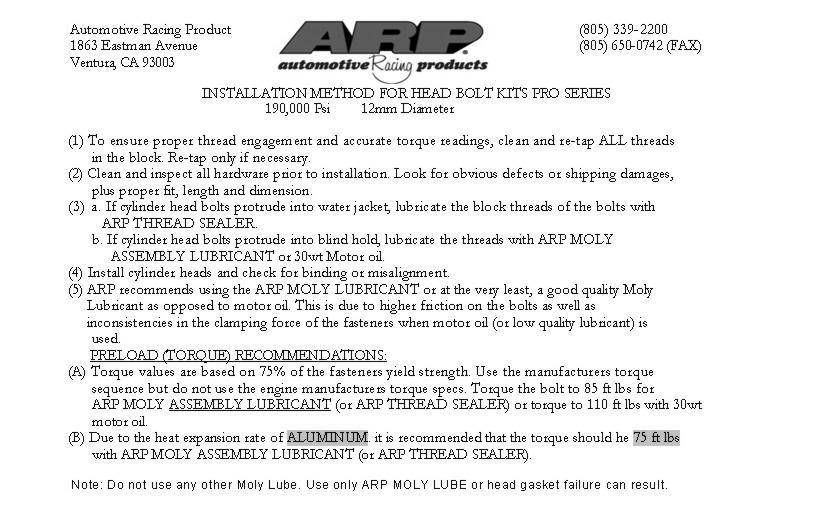

When you install them, screw them into the block, but only tighten them “hand tight” (in ARP’s words). And even though the spec sheet says you CAN use Loctite for installation, I definitely wouldn’t recommend it.

Here’s the problem, though: If I remember right, ARP’s specs for 7M studs have changed a little through the years, ranging from (I think) about 75 ft/lbs to 82ft/lbs. (A quick search on SM should turn up at least one thread that points this out.) For reference, my head studs were purchased from Summit Racing back in ’06. According to the sheet that came with mine, the studs are 12mm studs rated at 190,000PSI. The torque specs are supposed to be based on 75% of the stud’s yield strength. If you’d like-and if I get the chance to do so-I can scan the spec sheet and post it here or email it to you (just let me know). As far as the torque specs listed for mine go, the recommendation is 80ft/lbs if you’re using ARP’s moly lube (available through any ARP distributor), or 120ft/lbs if you’re using 30WT engine oil as lube. Additionally, while it’s not mentioned in the spec sheet, you’ll want to torque the nuts in three passes (again, this is ARP’s recommendation, not my opinion). If you use too many passes when you torque the nuts, supposedly the torque wrench won’t necessarily have enough variance between the torque figures for each pass to work properly. Basically, you can end up with uneven torque figures if you use too many passes to torque the nuts down.

And if all else fails, call ARP for a recommendation as to what to do. The phone number listed on my spec sheet is (805) 339-2200. But I’m thinking you’ll be fine if you hand tighten the studs, lube the threads and washers with ARP’s lube, and torque the nuts to 80ft/lbs in three passes. Oh, and don’t forget about retorquing them a few times.

Hope this helps…

Joe