figgie said:

I wonder if the Air Force would be willing to disclose the alloy used on the exhaust vanes of the GE-F101 engine that is used on the B-1, 30,000 lbs thrust on afterburners and those EGT are 2000+ degrees at the exit point

That would be Ti-35V-15Cr (Tiadyne 3515) a.k.a. alloy C, also used on the F-22 Raptors thrust vector nozzles.

Snowmongoose: Remote mounting the turbo would defiantly take care of the EGT problem, but I would have to go with Figgie on the idea that you will loose a good deal of exhaust gas energy over the distance. Plus those big V8 have the low down torque to pick up the extra weight of all the extra piping and components. And they are almost pumping twice as much air, without the aid of exhaust energy, as us at any given RPM

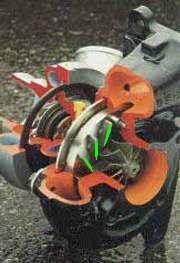

Just to give people an idea of what were talking about, here are some pictures of a VNT (Variable Nozzle Turbine) Turbo.

And this is the Porsches VTG (Variable Turbine Geometry)turbo – aka VGT turbo

Adjuster: That set up is very good, and probably very close to what Nissan is going to use.

Let’s talk about the benefits of Spark-Ignition Direct Injection for a moment.

Because of the ability to atomize and control the fuel better within the combustion chamber, it can cool the intake charge as well as create a stochimetric bubble with a lean mixture surrounding it and still control pre-ignition. Direct injection has the ability to operate at a very homogeneous mixture (lean: even to the point of 20:1) this can make for very good fuel consumption.

This is great news for economy cars, but what can it do for performance cars? Well it can allow for the use of higher compression pistons in boosted applications while maintaining control over pre-ignition. Proof of this is in the new Mazda CX7.

http://www.mazda.co.uk/AboutMazda/MazdaNews/LatestHeadlines/Articles/news 04-01-2006

It utilizes, spark ignition direct injection, on a 2.3 liter 4 cylinder motor with 9.5:1 compression. It’s peak torque of 258 ft/lbs is at 2500 RPM.

It’s a scary thought but this little 2.3 liter 4 banger produces more torque and at a lower RPM than our mighty 3.0 liter I6 7M.

The high compression pistons gives the motor a lot of off boost power, and at the same time allows the turbo to spool ultra quick, imagine what it could do with a VNT turbo.

So as we can see Direct injection as some very good benefits to offer the high performance market.

Now on to my original question. After doing some research this is what I think the motor will be like in the new GT-R.

Some say that they will use the 3.5L V6 from the VQ family. But industry experts say it more than likely will be a 3.7-4.0 liter V6 VQ motor. OK fine, I’ll take a 3.7 for my example.

3.7L V6 w/ Continuously Variable Valve Timing Control System (CVTCS)

9.5:1 or more Compression Ratio

COP ignition

Direct Injection Spark-Ignition

Intercooled Twin Garret Turbos with VNT technology

6-speed manual or CVT auto.

AWD( obviously, it’s a GT-R)

So what do you guys think, would this produce a motor with zero lag, and the ability to maintain almost continually a state of positive manifold pressure, without it dropping in to the negative range except when the throttle is shut?

All of this technology exists but it just needs to be brought together