Very cool. Saw this design a year ago or so... When you have two compressors feeding a consolidated outlet, this actually allows for more boost at lower turbo shaft speeds. This would significantly increase the longevity of the unit. And with the variable veins, the efficiency range is greatly increased.

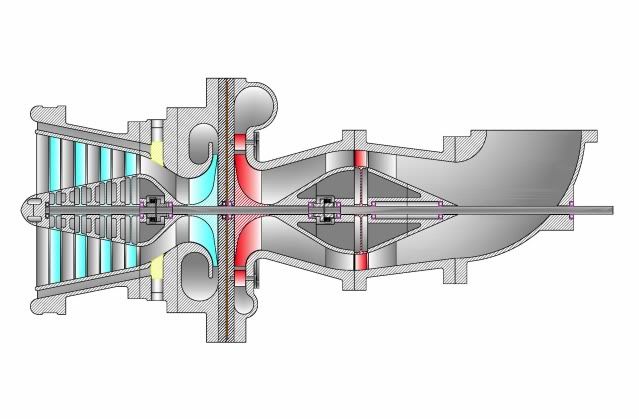

I've toyed with the idea of a turbocharger design with an axial pre-compressor (like in a jet engine) to pre-compress the air before it is then compressed more by the centrifugal compressor... I even did a crazy design for ridiculous boost pressures with an axial turbine after the main turbine with variable veins to further scavenge energy from the exhaust gases... Here's a little drawing I did in autocad for fun one day:

The turbo shaft extends out past the down pipe for another concept idea which was to make further capture and re-use the exhaust gas energy by either driving a specially designed alternator or mechanically linked back to the crankshaft (already in use by Volvo and Detroit Diesel in highway tractors).

Turbochargers are one of the best inventions of the last century. Seeing how many vehicles are now available with turbos from the show-room, I think we're only going to see more and more as time goes on and the technology further evolves. I've also seen some companies working on developing turbochargers with integrated electric motors/alternators, which will help extend the efficiency range, reduce lag and relieve the load on the vehicles main alternator when the turbo is working.

Great post. Love this stuff!