Project Git 'er done!: Stages 1, 2, 3, 4....Stage 5- Reassembly after 13 years!!!

- Thread starter supraguy@aol

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

akito;1989665 said:That's a nice set up. I love your ideas dude!

I hate all his ideas...

why?

'cause he's putting them on the WRONG CAR. (maybe I should text you the location of the RIGHT car...)

Ha!

So, got home today, and dug into my boxes:

Dropped the IC pipe off for extension, should be ready Wednesday or Thursday.

Received my new wheel lugs. My originals were nice, but too narrow. Needed more seating surface. They're kinda bling, but what the heck.

Also...a bit of customization, to make the wheels look more like they belong...

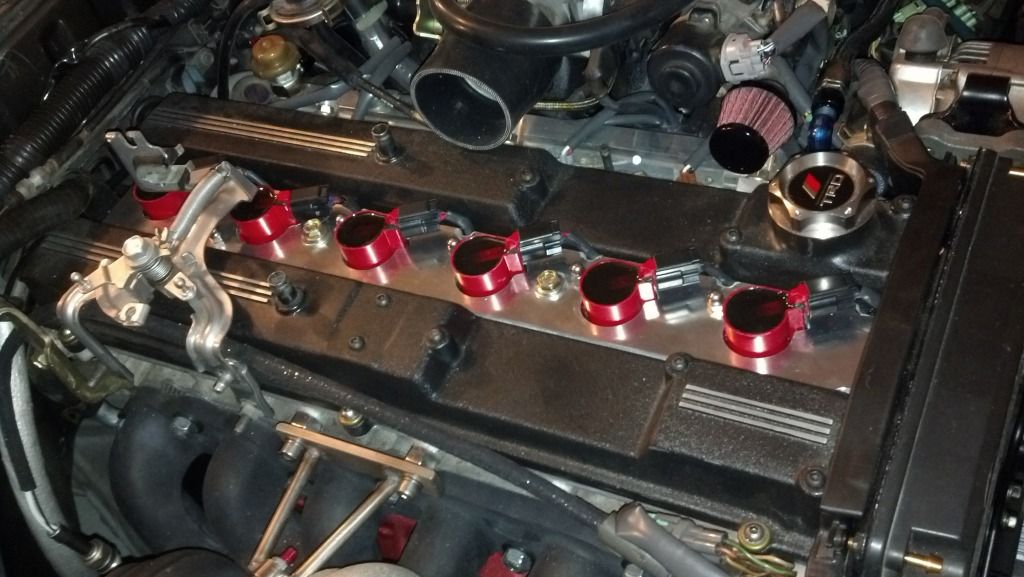

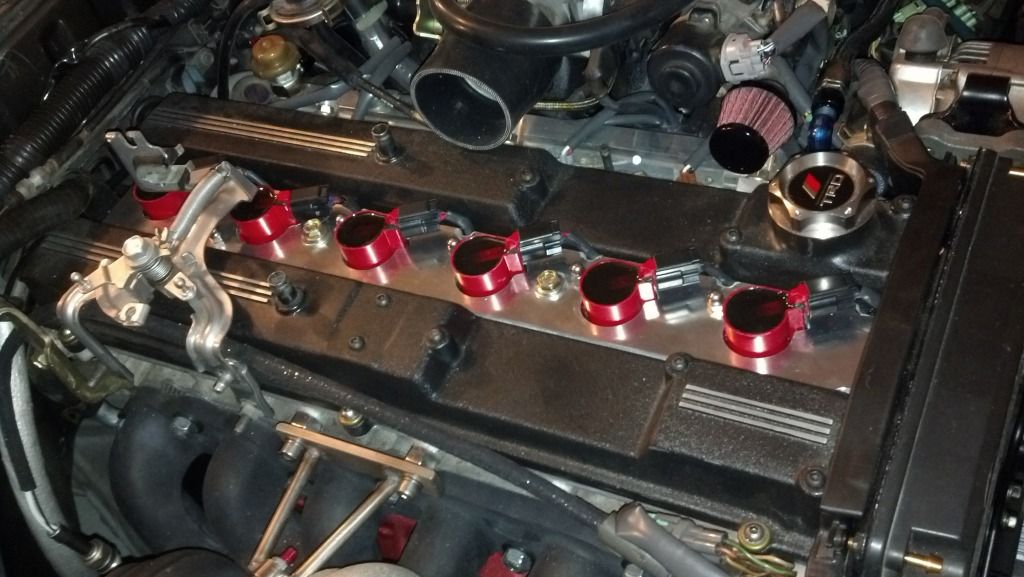

Then, I finished modding the Nathan plate, to fit with my throttle bracket assembly, as well as incorporate the DG528 at cylinder #5. Then I installed the coil harness...Underneath...

So, got home today, and dug into my boxes:

Dropped the IC pipe off for extension, should be ready Wednesday or Thursday.

Received my new wheel lugs. My originals were nice, but too narrow. Needed more seating surface. They're kinda bling, but what the heck.

Also...a bit of customization, to make the wheels look more like they belong...

Then, I finished modding the Nathan plate, to fit with my throttle bracket assembly, as well as incorporate the DG528 at cylinder #5. Then I installed the coil harness...Underneath...

Last edited:

I only stuck with it because I didn't see an FFIM that I liked.

Nearly every single one requires that you give up ac and/ or relocate the battery. The one that CarlosPTR210 makes, however, is appealing... but it's something I can do later on if I really want to. Besides- my power goals don't really necessitate it. I like to envision my car as being an upgrade to stock without really changing the basic layout.

Nearly every single one requires that you give up ac and/ or relocate the battery. The one that CarlosPTR210 makes, however, is appealing... but it's something I can do later on if I really want to. Besides- my power goals don't really necessitate it. I like to envision my car as being an upgrade to stock without really changing the basic layout.

My favorite post in the whole thread. Lolsupraguy@aol;1990698 said:

Really like your build man, seeing you engine run was awesome

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

So the big speedbump on my build, has been the ac system.

I didn't want to install the dash till I could confirm that what's behind it(the ac core) was leak-free.

I pressurized the system with argon, and have found that it bleeds off over a reltively short period of time. I tried spraying each connection with soapy water, but I get no bubbles anywhere.

Also, no hissing sound of escaping gas. The only part of the system that hasn't been replaced, is the compressor itself.

...a new compressor is on the way.

I didn't want to install the dash till I could confirm that what's behind it(the ac core) was leak-free.

I pressurized the system with argon, and have found that it bleeds off over a reltively short period of time. I tried spraying each connection with soapy water, but I get no bubbles anywhere.

Also, no hissing sound of escaping gas. The only part of the system that hasn't been replaced, is the compressor itself.

...a new compressor is on the way.

Glad to see you got it running, hopefully the new compressor fixes the AC problem. I know you are going to need that down here in the south with our humidity and heat during the summer.

1986.5supra_kid

Rice? No its Corn (E85)

saw your videos on FB. now you can go to the meets while siting on a bucket  until you finish the interior

until you finish the interior

Riiiight.

Nah. This car won't be on the road till its painted.... sometime around 2018AD.

Update- I transferred over my harness to the new dash, so that can be installed this week.

Nah. This car won't be on the road till its painted.... sometime around 2018AD.

Update- I transferred over my harness to the new dash, so that can be installed this week.

Any close-ups of where the throttle linkage goes through the COP plate? Is it right in the middle of the coil #5 mounting point or off a bit?

I would say off a bit. The #5 coil mounting hole would be on the innermost edge of where you would creat a larger hole for the bracket post. What i needed to do was get that side of the bracket to sit slightly higher, but i didn't want to cut/ weld a set of higher mounts on the other end. So what i ended up doing is tilting it. Hard to explain. Im out of town for the next couple of days. When i get home, i'll take closeups and post a more detailed description, probably in Morganson's thread.

So, if I haven't already mentioned, the roadblock to my flow of progress has been the ac system. I have had a not-so-slow leak in it, when I check under vacuum. And there was no way that I was going to reinstall the dash, in case the leak came from the evap core.

So, instead I decided to pressurize the system to see if I could locate the leak by sound, or using a soap spray to identify bubbles. I connected an adapter to my welding(argon) tank, and ran that into the high and low sides of the system at 40psi, and sure enough, it would leak down to zero in about 15 minutes. Unfortunately, I could not find any leaks, or hear any hissing.

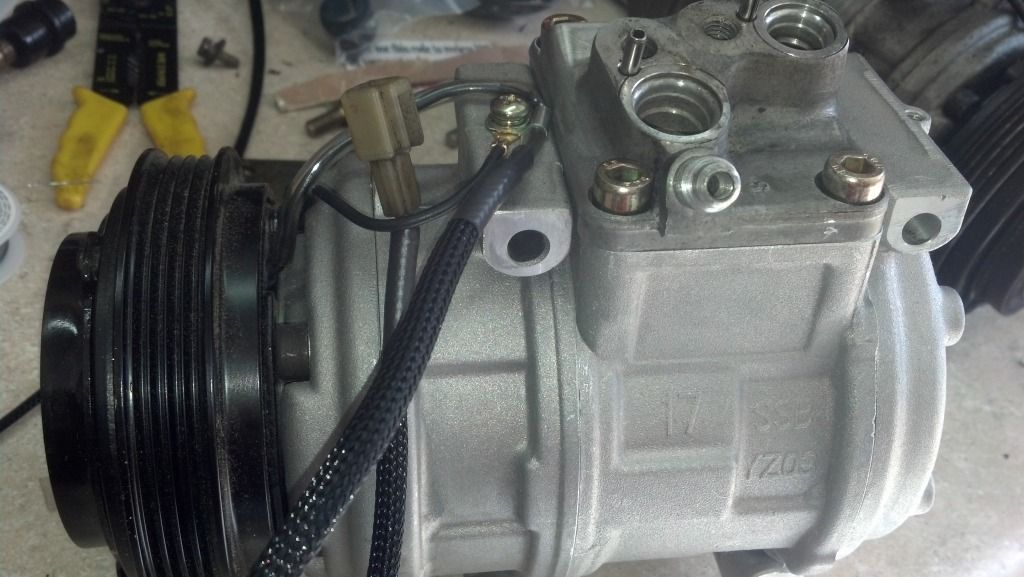

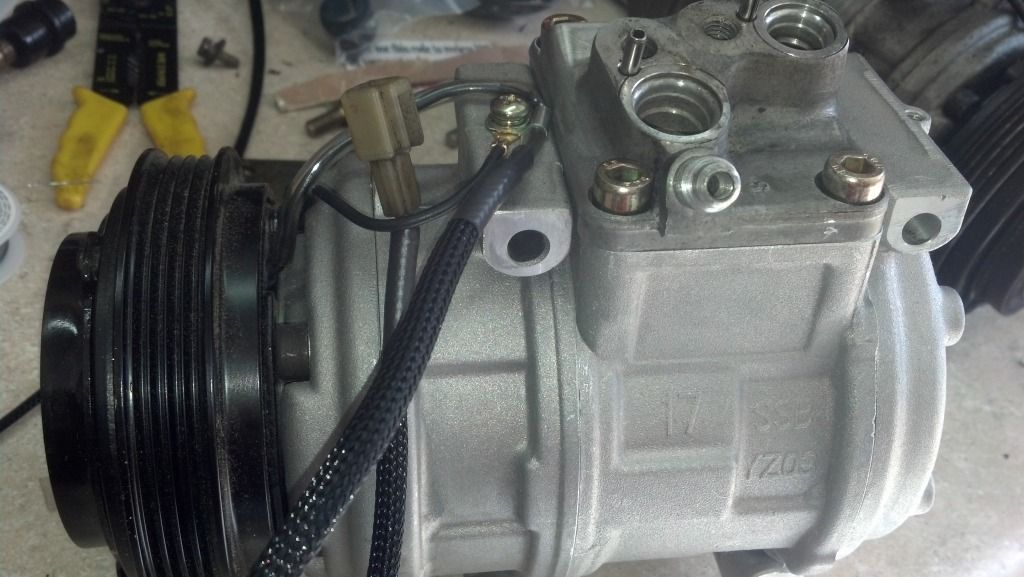

The entire system is brand new- new core, condenser, expansion valve, drier, high/low pressure lines, and all O-rings. Everything, except the compressor itself. So I decided to just blindly throw money at the problem, and bought a new compressor.

It worked!

Apparently, it was leaking from either the case seal, or shaft seal. I just finished installing it, and the pressure hasn't dropped a single psi in 15 minutes.

This means That I can now finally install everything- the dp/ exhaust, the heater core, the dash, and start planning out stage 3- interior.

Old and new.

New one, with the top plate and plug swapped over.

New unit, installed.

I expect the pace to pick up a bit now, on the completion of stage 2.

So, instead I decided to pressurize the system to see if I could locate the leak by sound, or using a soap spray to identify bubbles. I connected an adapter to my welding(argon) tank, and ran that into the high and low sides of the system at 40psi, and sure enough, it would leak down to zero in about 15 minutes. Unfortunately, I could not find any leaks, or hear any hissing.

The entire system is brand new- new core, condenser, expansion valve, drier, high/low pressure lines, and all O-rings. Everything, except the compressor itself. So I decided to just blindly throw money at the problem, and bought a new compressor.

It worked!

Apparently, it was leaking from either the case seal, or shaft seal. I just finished installing it, and the pressure hasn't dropped a single psi in 15 minutes.

This means That I can now finally install everything- the dp/ exhaust, the heater core, the dash, and start planning out stage 3- interior.

Old and new.

New one, with the top plate and plug swapped over.

New unit, installed.

I expect the pace to pick up a bit now, on the completion of stage 2.

Today(so far), I've reinstalled the DP, and exhaust, hopefully for the last time.

And...Here's a quick video of the first 'sound' through the exhaust.

[video=youtube_share;IHv5Ve8Btr8]http://youtu.be/IHv5Ve8Btr8[/video]

And...Here's a quick video of the first 'sound' through the exhaust.

[video=youtube_share;IHv5Ve8Btr8]http://youtu.be/IHv5Ve8Btr8[/video]

Last edited: