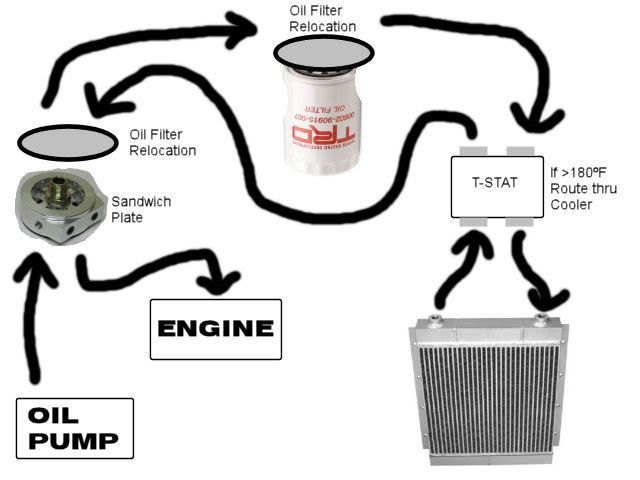

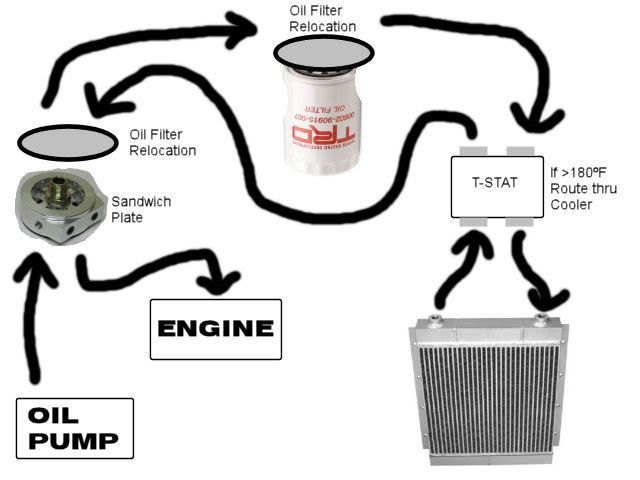

So as part of my rebuild, I'm thinking I should try improve the oil system to help avoid future rod knock. I decided not to shim oil pump because it doesn't start opening until 40psi anyway. I did put in a brand new oil pump in though. So instead I thought I'd stop the unnecessary dumping of oil back into the pan by going with a full flow oil cooler setup.

Please take a look at my flow diagram and let me know if this is the right idea. I want to add an aftermarket oil pressure sensor and an oil temperature sensor so that is why the sandwich plate is in there. I may find other ways to add those sensors, but that's what I'm going with for now.

Please take a look at my flow diagram and let me know if this is the right idea. I want to add an aftermarket oil pressure sensor and an oil temperature sensor so that is why the sandwich plate is in there. I may find other ways to add those sensors, but that's what I'm going with for now.