I'll do point form of the history to attempt to keep it brief.

-Purchased the car about 4 years ago. Had a broken windshield and missing front bumper at the time. Replaced everything it needed with my father. (This is my first car)

-Drove the car for a year in stock form, including all winter. I live in Nova Scotia so we get a fair amount of snow. I quickly learned how to deal with a lot of oversteer. This sparked my interest in being able to keep the car sideways on dry pavement. The image of a torque monster slowly grew in my mind.

-I've worked at an engine shop since I graduated from high school. My father owns a small block camaro and I've worked with sbc's a lot at work. A 2jz swap was always a dream of mine but after doing the math I came to the conclusion that I could get more power for far less money with a small block swap. So i started work on it.

-In my spare time at work I built a Full roller 350 with about 10:1 comp. Ported a set of 305HO heads and a no-name intake up so it could breathe really well. (the heads lost several pounds each in the process) And threw it all together with all the tricks and go-fast parts I could afford at the time. It makes about 350hp and 370ft/lbs of torque. Nothing special, but should work ok with my 150hp shot of nitrous. (and should do it all very reliably)

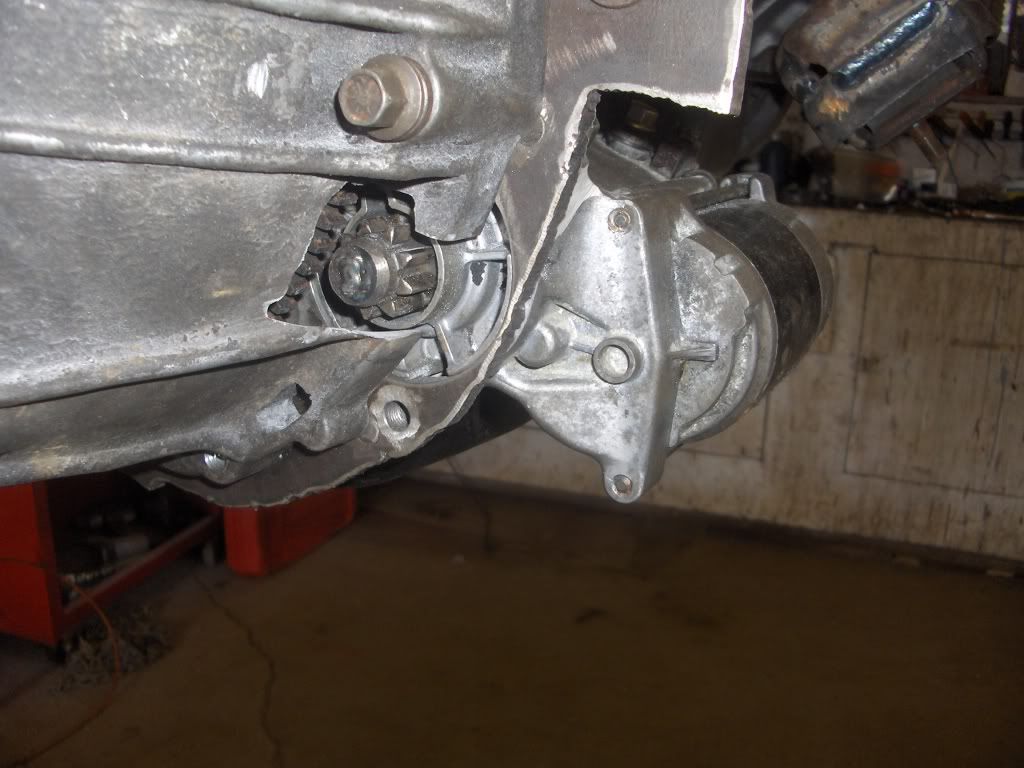

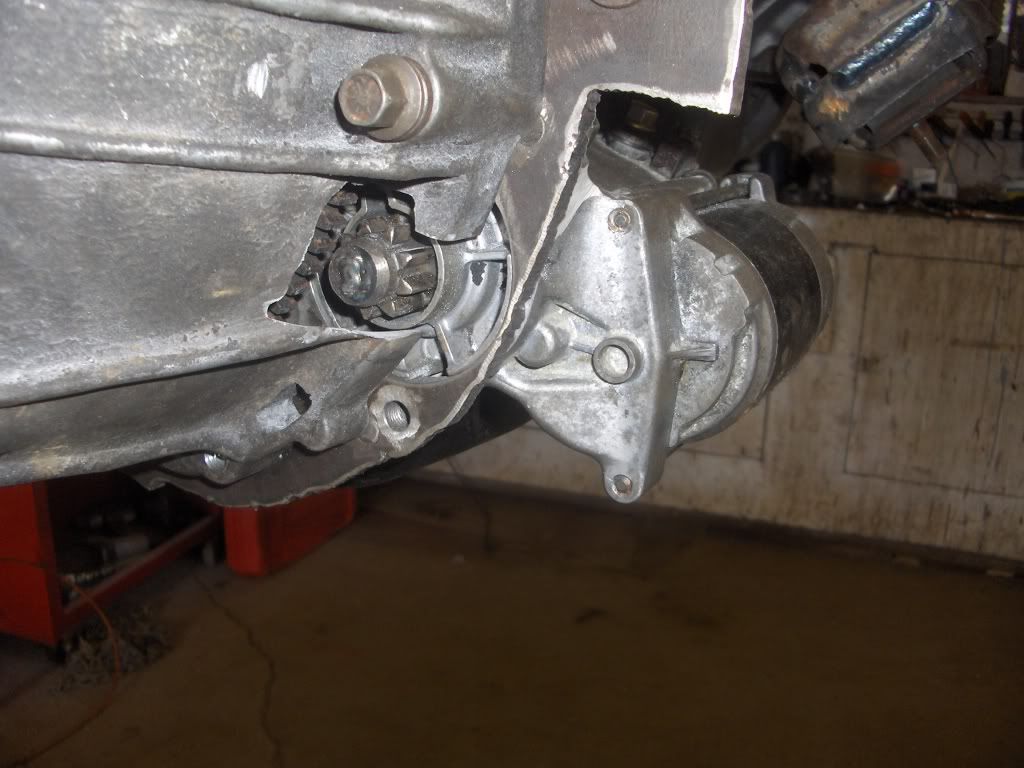

-After that was done I built a trans adapter plate so the sbc could mount up to the stock w58. (I am well aware this won't last for long, so when it breaks I'll be going r154) With a couple of adapters I also got the toyota flywheel mounted on and everything checked out. None of it looks all that great but the accuracy of the system is far beyond OEM specs.

I mounted the toyota started to the adapter plate, the hole in the bellhousing has been welded in properly.

To use the factory 7m alternator and power steering pump I built custom brackets and cut up the old 7m pulley so that it would mount to the chev harmonic balancer.

-My father and I cut all the rust out of the car, there was a ton of it. Welded in all new metal, smoothed it all out and threw a quick coat of paint on it. I picket up an aftermarker front bumper that had been smashed all to hell. About 5 pieces if i remember correctly. I fiber glassed it all back together and mounted it. The rims are mustang 18's. I have since gotten rid of them so don't flame lol

-I mounted the block in about a weekend. wasn't all that tough of a job. I sat it as low and far back as I could. The biggest job was the headers. I used these http://cgi.ebay.com/ebaymotors/NEW-Chevy-305-350-SBC-Chrome-Chevelle-Exhaust-Headers_W0QQcmdZViewItemQQhashZitem4ced0924b6QQitemZ330394313910QQptZMotorsQ5fCarQ5fTruckQ5fPartsQ5fAccessories

The pass side fits with minor floor modification and the drivers side needed to be cut apart and re-welded. No biggie, they were cheap. They are now wrapped in black header wrap and look pretty nice.

-My exhaust is full dual 3" and it runs through a dual in/dual out Magnaflow muffler.

-Cooling is taken care of with a Mishimoto rad, dual 14" electric fans and a high volume electric water pump.

-Fuel is delivered with the stock pump with a holley blue inline pump and FPR.

-I have re-upholstered a lot of the interior and replaced the 500lb seats with a cheap set of apc's to save weight. The rear seats have been removed and I swapped the factory spare with a "donut" spare from a mustang so that The inside of my hatch is flat on bottom without using that damn piece of wood.

I have a little wiring left and I need to figure out my intake and she'll be complete! My plan is to have it done for early summer. We'll see how many bugs come up.

-Purchased the car about 4 years ago. Had a broken windshield and missing front bumper at the time. Replaced everything it needed with my father. (This is my first car)

-Drove the car for a year in stock form, including all winter. I live in Nova Scotia so we get a fair amount of snow. I quickly learned how to deal with a lot of oversteer. This sparked my interest in being able to keep the car sideways on dry pavement. The image of a torque monster slowly grew in my mind.

-I've worked at an engine shop since I graduated from high school. My father owns a small block camaro and I've worked with sbc's a lot at work. A 2jz swap was always a dream of mine but after doing the math I came to the conclusion that I could get more power for far less money with a small block swap. So i started work on it.

-In my spare time at work I built a Full roller 350 with about 10:1 comp. Ported a set of 305HO heads and a no-name intake up so it could breathe really well. (the heads lost several pounds each in the process) And threw it all together with all the tricks and go-fast parts I could afford at the time. It makes about 350hp and 370ft/lbs of torque. Nothing special, but should work ok with my 150hp shot of nitrous. (and should do it all very reliably)

-After that was done I built a trans adapter plate so the sbc could mount up to the stock w58. (I am well aware this won't last for long, so when it breaks I'll be going r154) With a couple of adapters I also got the toyota flywheel mounted on and everything checked out. None of it looks all that great but the accuracy of the system is far beyond OEM specs.

I mounted the toyota started to the adapter plate, the hole in the bellhousing has been welded in properly.

To use the factory 7m alternator and power steering pump I built custom brackets and cut up the old 7m pulley so that it would mount to the chev harmonic balancer.

-My father and I cut all the rust out of the car, there was a ton of it. Welded in all new metal, smoothed it all out and threw a quick coat of paint on it. I picket up an aftermarker front bumper that had been smashed all to hell. About 5 pieces if i remember correctly. I fiber glassed it all back together and mounted it. The rims are mustang 18's. I have since gotten rid of them so don't flame lol

-I mounted the block in about a weekend. wasn't all that tough of a job. I sat it as low and far back as I could. The biggest job was the headers. I used these http://cgi.ebay.com/ebaymotors/NEW-Chevy-305-350-SBC-Chrome-Chevelle-Exhaust-Headers_W0QQcmdZViewItemQQhashZitem4ced0924b6QQitemZ330394313910QQptZMotorsQ5fCarQ5fTruckQ5fPartsQ5fAccessories

The pass side fits with minor floor modification and the drivers side needed to be cut apart and re-welded. No biggie, they were cheap. They are now wrapped in black header wrap and look pretty nice.

-My exhaust is full dual 3" and it runs through a dual in/dual out Magnaflow muffler.

-Cooling is taken care of with a Mishimoto rad, dual 14" electric fans and a high volume electric water pump.

-Fuel is delivered with the stock pump with a holley blue inline pump and FPR.

-I have re-upholstered a lot of the interior and replaced the 500lb seats with a cheap set of apc's to save weight. The rear seats have been removed and I swapped the factory spare with a "donut" spare from a mustang so that The inside of my hatch is flat on bottom without using that damn piece of wood.

I have a little wiring left and I need to figure out my intake and she'll be complete! My plan is to have it done for early summer. We'll see how many bugs come up.