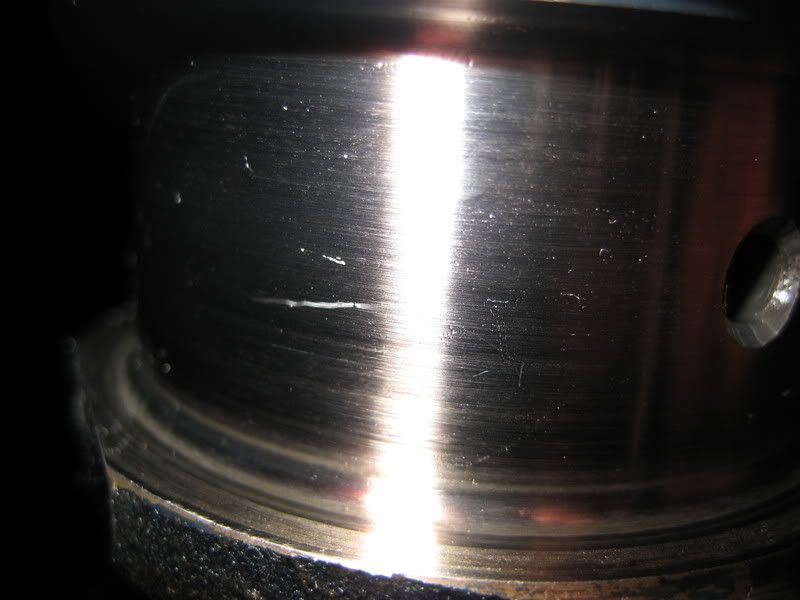

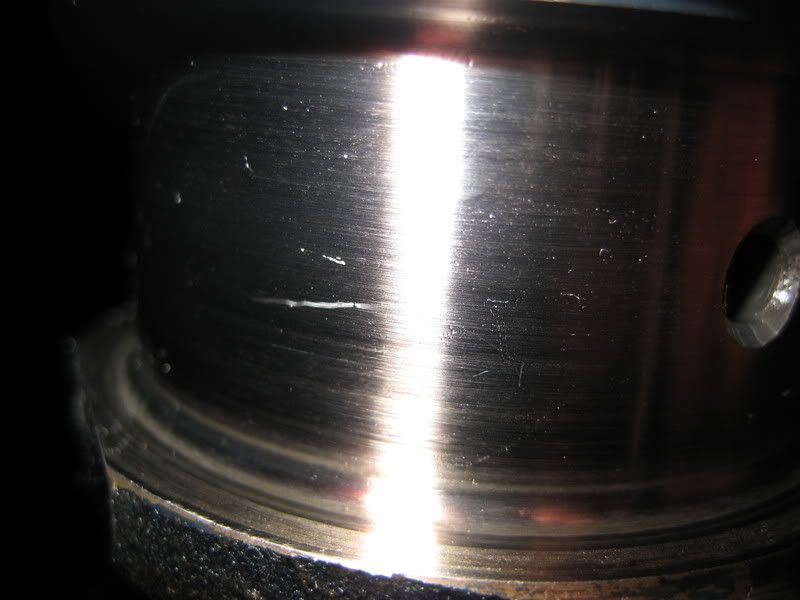

I was mic'ing all the journals on my crank today so I can figure out what standard Toyota bearing to get. As I was removing the mic from one of the rod journals, I left a noticeable scratch. I can feel a slight dip with my fingernail. All my rod journals are at the lower limit for use with standard bearings right now, so I can either use it as is, or have it ground for an oversize bearing.

All little scratches are just specs of dust that seem to collect on the journals.

No Flash

Flash

All little scratches are just specs of dust that seem to collect on the journals.

No Flash

Flash