Okay, after swapping in a 7M-GTE which had been sitting for an unknown period of time, and had (Surprise surprise) a BHG, got rod knock.

Bought another 7M-GTE which had been pulled, and disassembly started for $250, which I was originally just going to swap in. Well, currently I'm glad that I didn't do that. Next the idea was to do the same as what I did last time, pull the head off and replace all of the gaskets and seals. The addition this time was to also change out the oil pump which I did not do last time.

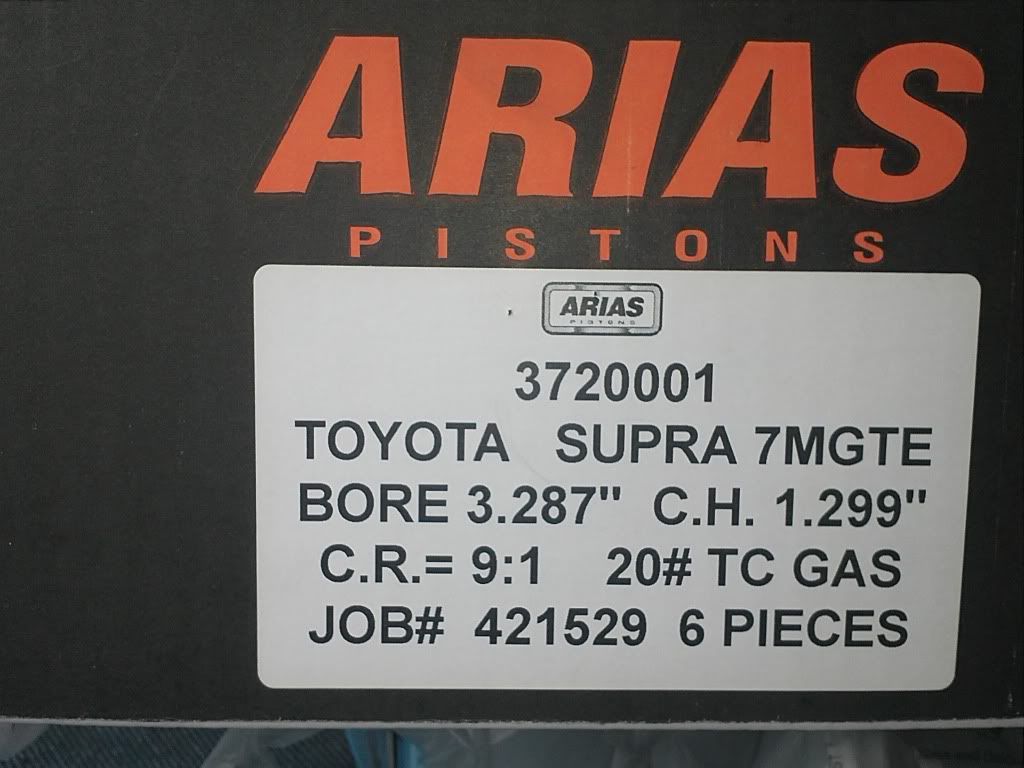

Asked around here, and... Well, it's going to be a larger project than that. New rings and bearings, MHG, ARP studs... Well, a pretty complete build, really. My power goals are not extravagant, but I'd like to be able to make more than 400WHP without having to open the block again, so obvious weak points should be avoided.

I can't afford to just take the engine to a builder and say "Make it so" so, will be doing what I can by myself.

Anyway, started with tear down today.

Timing cover, waterpump removed

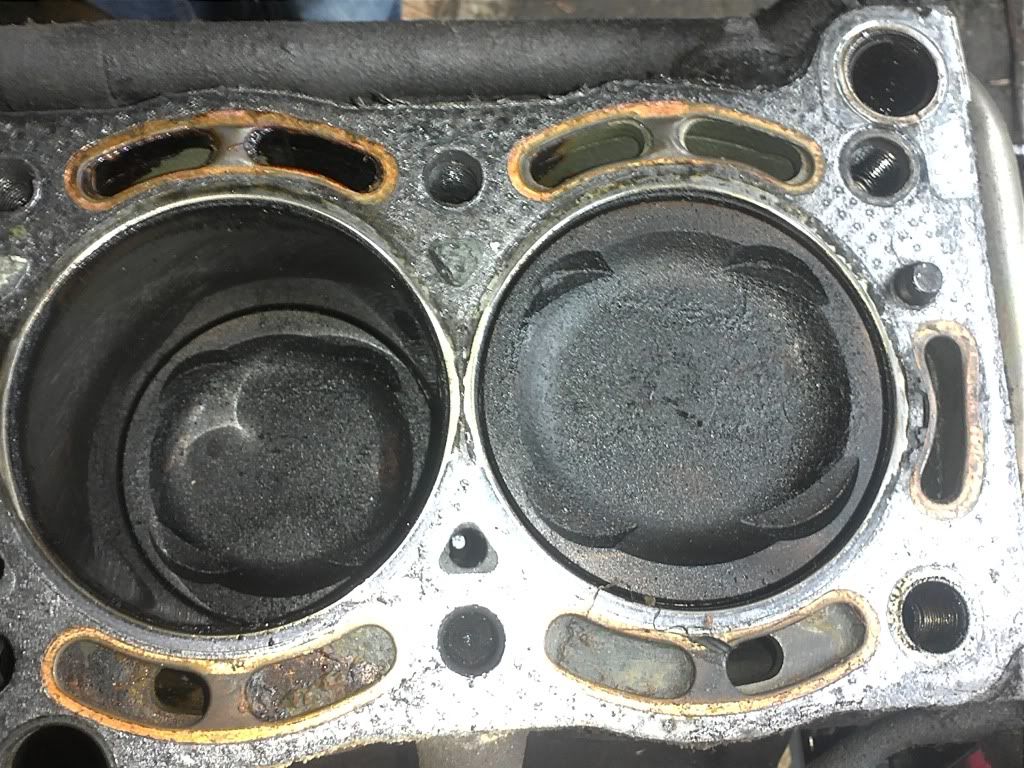

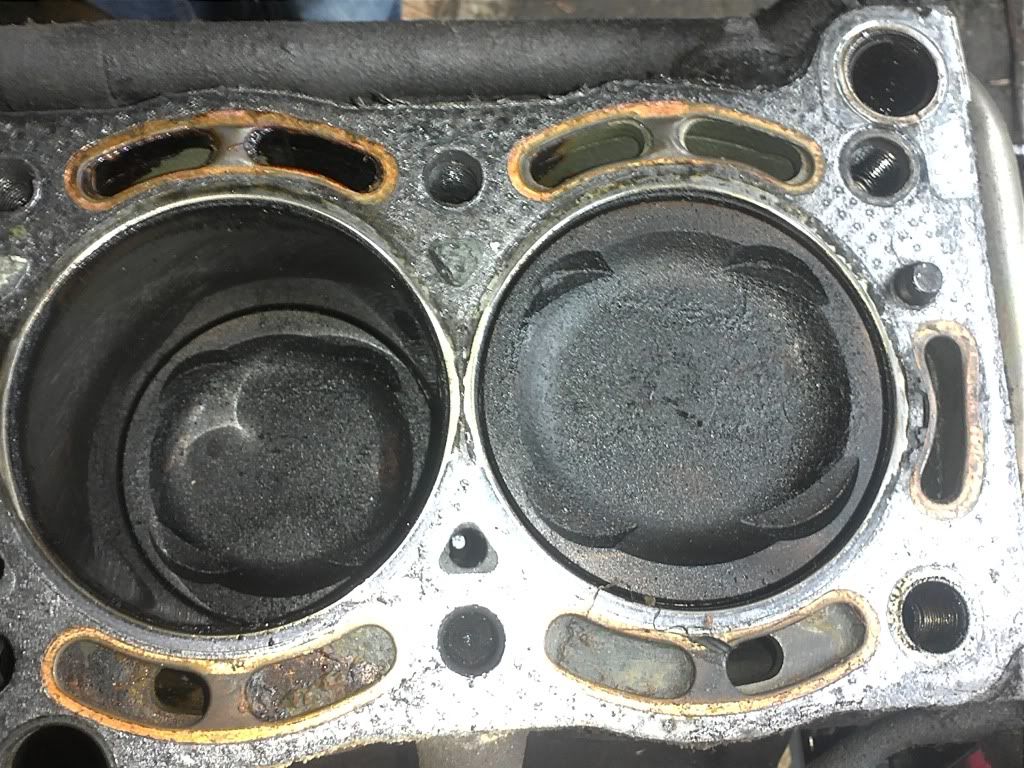

Head gasket, Cyl 1&2

Cyl 3&4

Cyl 5&6. Oh look, what a surprise, the HG was going out at #6.

The head on blocks.

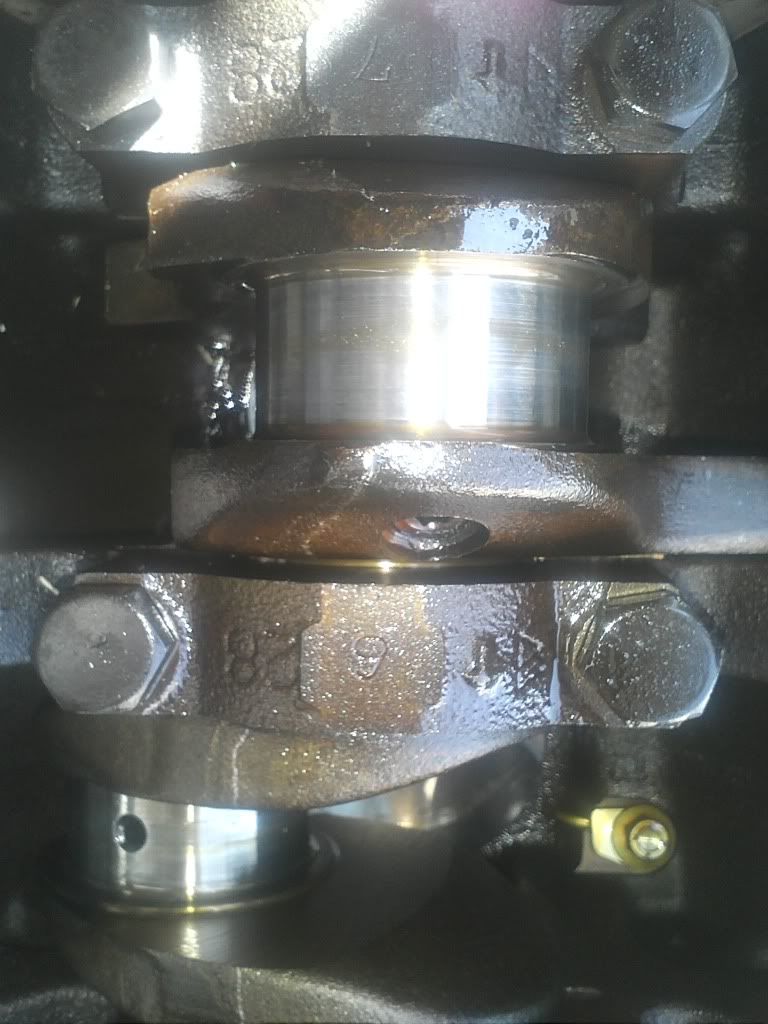

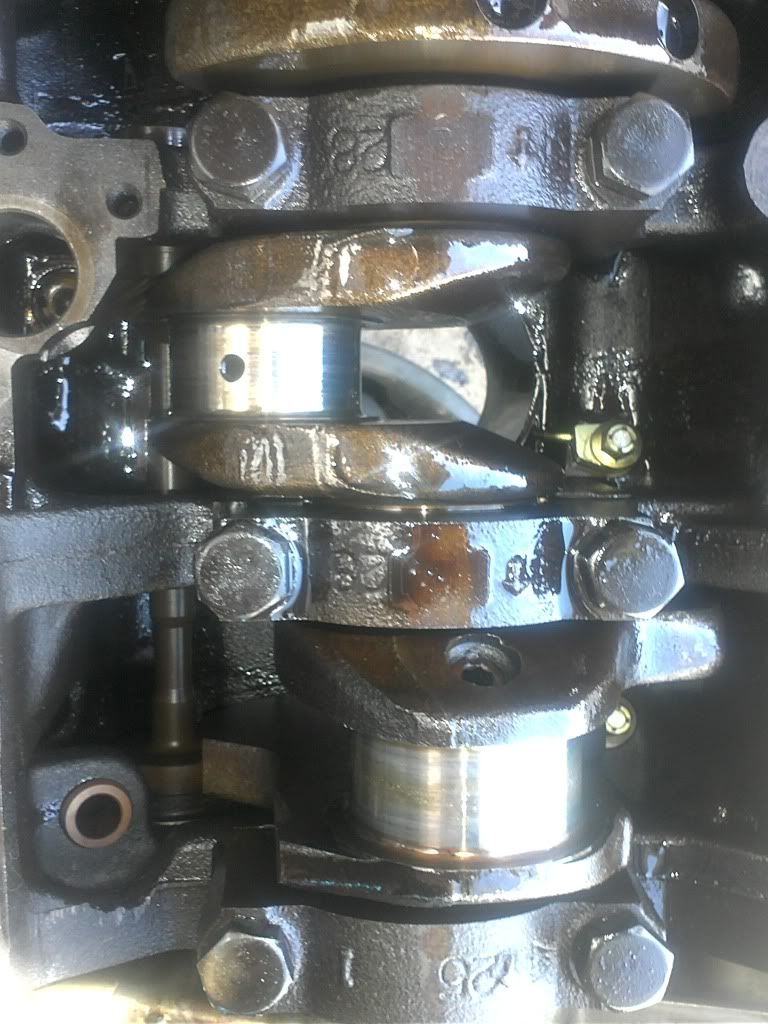

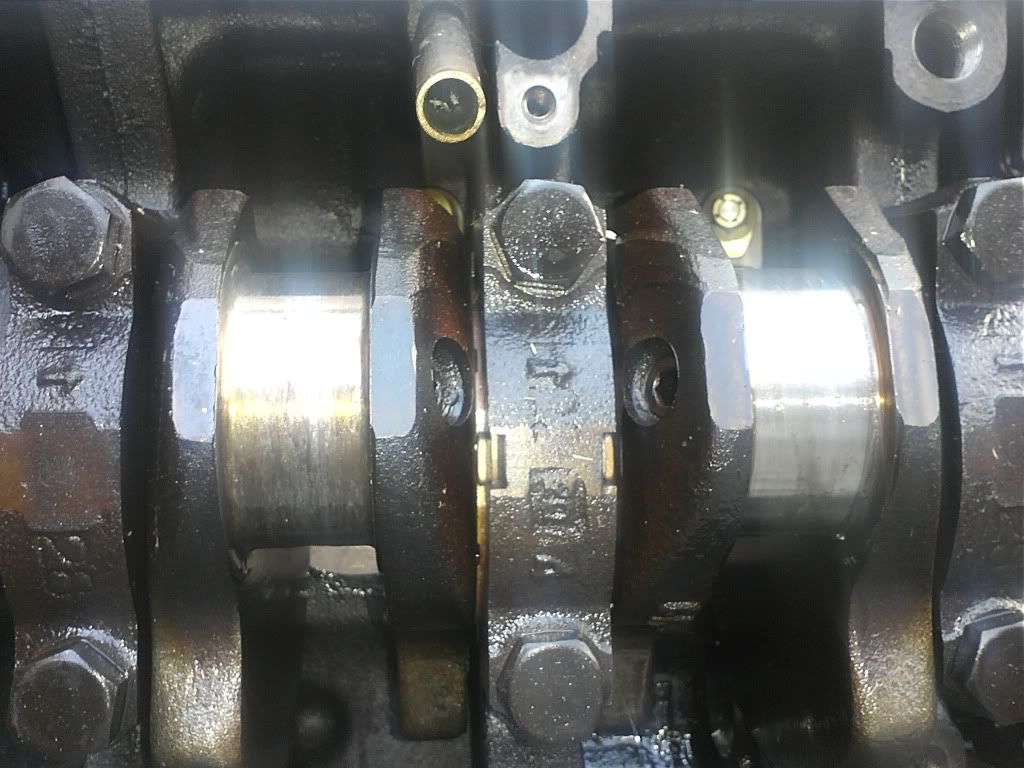

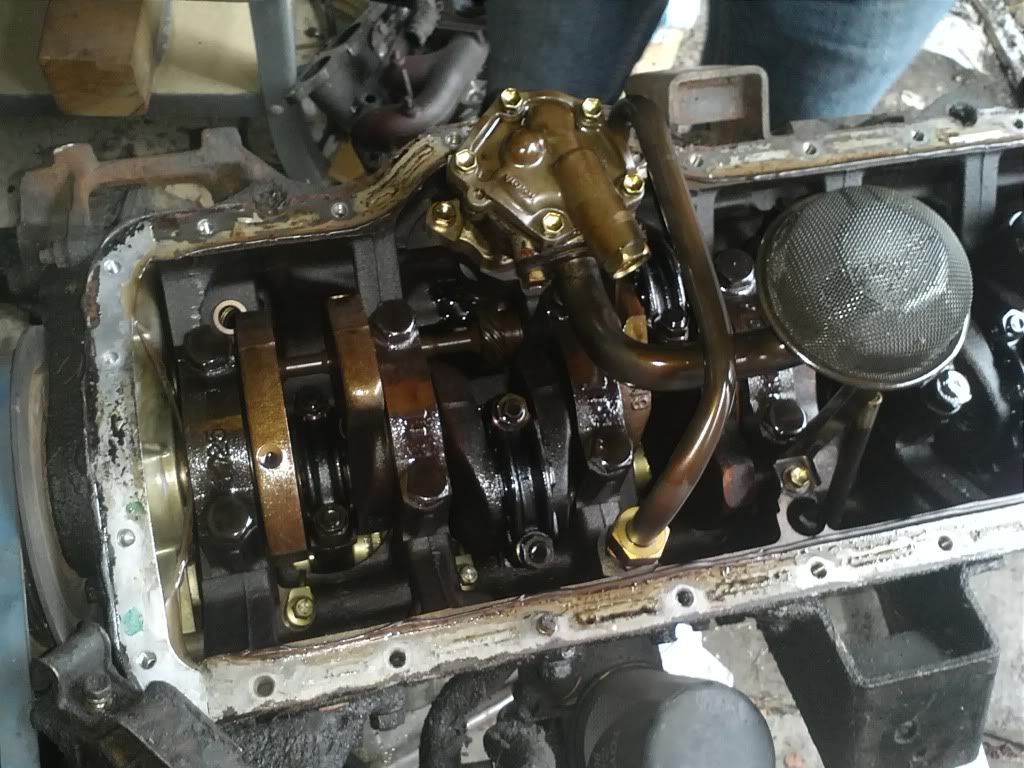

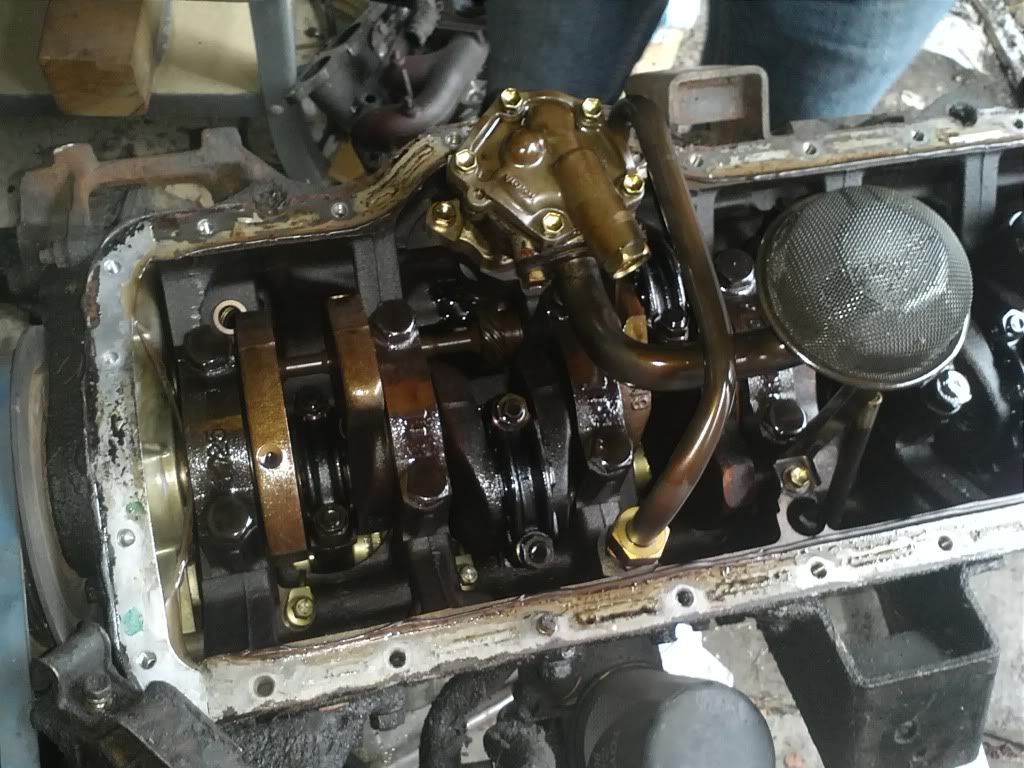

Turn the engine over, remove pan

Otherwise, removed a few other pieces here and there from the engine, the water neck, heater core pipes, and other misc bits and pieces as opportunity presented itself. Things look pretty grubby in there, but the head bolts came out looking nice and clean. Surprisingly so, actually. One head bolt was a bit troublesome. At least none of them were loose.

Bought another 7M-GTE which had been pulled, and disassembly started for $250, which I was originally just going to swap in. Well, currently I'm glad that I didn't do that. Next the idea was to do the same as what I did last time, pull the head off and replace all of the gaskets and seals. The addition this time was to also change out the oil pump which I did not do last time.

Asked around here, and... Well, it's going to be a larger project than that. New rings and bearings, MHG, ARP studs... Well, a pretty complete build, really. My power goals are not extravagant, but I'd like to be able to make more than 400WHP without having to open the block again, so obvious weak points should be avoided.

I can't afford to just take the engine to a builder and say "Make it so" so, will be doing what I can by myself.

Anyway, started with tear down today.

Timing cover, waterpump removed

Head gasket, Cyl 1&2

Cyl 3&4

Cyl 5&6. Oh look, what a surprise, the HG was going out at #6.

The head on blocks.

Turn the engine over, remove pan

Otherwise, removed a few other pieces here and there from the engine, the water neck, heater core pipes, and other misc bits and pieces as opportunity presented itself. Things look pretty grubby in there, but the head bolts came out looking nice and clean. Surprisingly so, actually. One head bolt was a bit troublesome. At least none of them were loose.